The opt

o-isolation will prevent any accidental 'let the smoke out' events when power from another source gets into a sensor wire.

Wiring should be high temperature (insulation) since any accidental contact with exhaust manifolds, etc. could result in shorts which could smoke the D/A shield.

I'm thinking plenum-grade CAT-5

When you say raw water in and out, I assume temp and not water flow?

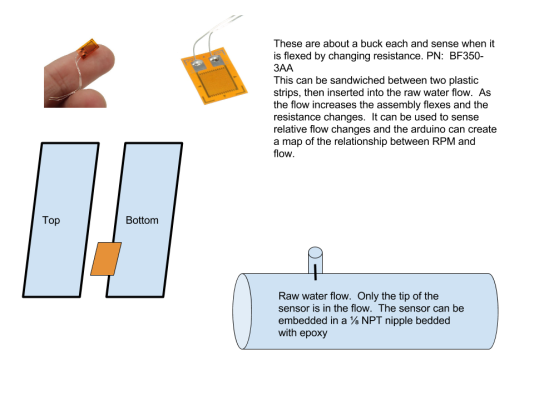

Yes, but I've seen some cheap flow sensors that report volume, but I doubt it's marine quality

you also may want to consider a temp sensor on the shaft seal (packing temp).

Great idea, Would you recommend this in V1? Would be easy with a 1-wire sensor since it woudn't take more pins

Also, a temp sensor for engine room? fire sensor?

Engine room temp is included in V1. Not a fire sensor though. I was thinking a subsequent version but we take something off of V1 to accommodate the fire sensor. A small concern I have is when this system starts to take the place of what should be a proven marine grade system, like a fire alarm or carbon monoxide tester.

And you may want to make the provision available for twin engines (two arduino)

plan on being able to log data points to be able to create a "normal" for each sensor. That way, you can quickly see a rising / falling trend and sudden out of normal data ranges.

I'm thinking alerting is in Version 2, but that's only because I want to have something simple and easy for the first version to increase adoption. Using the data for alerting or logging is very valuable, but is a bit more complicated since it involves a configuration capability and storing a map of data to determine the trend.

I'd like to have a data logger capability in some future version that stores all the measurements, with a timestamp onto a flash card

I will see if I can get the code for an old compiler / macro language I wrote many years ago. I think I could adapt it to be able to do ad-hoc coding.

What OS will the Arduino be running? What dev kit would you start with?

The beauty of Arduino is there is no OS to concerned with. You just plug the board into your PC/Mac/Linux using a USB. Then you deploy the code to the arduino using an open source tool that is downloaded from the Arduino site. This is the same tool you can use for your IDE, so it you want to see the code or even change it, it's simple. As for the dev kit, I was thinking just the Uno board ($25)

My son in law is an arduino & android developer (current) and I'm ancient developer from DOS, OS/2, Windows, and a bit of IOS development lately. i think this would be a fun project and would enjoy tinkering with it.

With your DOS through IOS skills you would easily pick up arduino. There are thousands of tutorials on everything from "hello word" through voice recognition.

While I don't have a boat and can't get out on one now (medical) my brain wanders aboard almost daily

STu