R_p_ryan

Senior Member

- Joined

- Dec 11, 2014

- Messages

- 171

- Location

- USA

- Vessel Name

- Shellbourne

- Vessel Make

- 1978 Mainship 34 Perkins T6.354

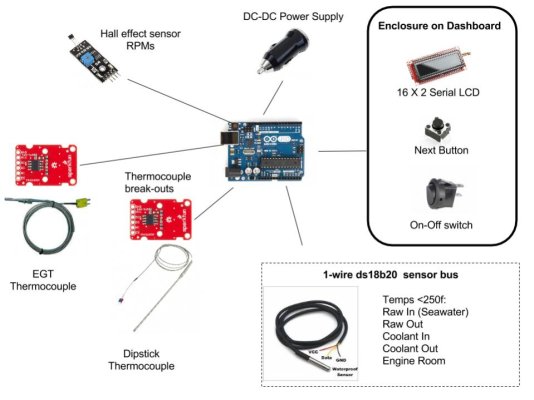

Is anyone interested in a DIY engine monitoring system based on the Arduino board? They're cheap and I can program them. Basically I'm thinking of having a board, a simple LCD display and a "next" button.

There would be set of sensors, such as tach, oil temp, water temp, boost, EGT, that you would need to install. Could even add things like raw water inlet temp, raw water oulet temp, etc...

I'd be happy to do the open-source programming and publish the schematics.

Boost and EGT are based on 1/4" npt sensor that needs to be drilled, tapped. Tach requires a bracket and 2 tiny magnets added to each side of the flywheel. Oil and water temps would have a few options, some as simple as using JB-Weld to bond the sensors to the hot and cold sides of the oil cooler. In those cases the values would be more for comparison and getting a baseline since they would not be accurate.

Total price for the board and a few sensors would be less than $100 and you'd get it all from Amazon.

Base board:

http://www.amazon.com/arduino-org-A...e=UTF8&qid=1450373441&sr=8-2&keywords=arduino

Temp sensors (5 for $12):

http://www.amazon.com/Vktech-DS18b2...78&sr=8-1&keywords=arduino+temperature+sensor

Tach sensor:

http://www.amazon.com/SainSmart-Eff...73556&sr=8-1&keywords=arduino+magnetic+sensor

EGT Sensor:

http://www.amazon.com/SainSmart-MAX...50373612&sr=8-1&keywords=arduino+thermocouple

There would be set of sensors, such as tach, oil temp, water temp, boost, EGT, that you would need to install. Could even add things like raw water inlet temp, raw water oulet temp, etc...

I'd be happy to do the open-source programming and publish the schematics.

Boost and EGT are based on 1/4" npt sensor that needs to be drilled, tapped. Tach requires a bracket and 2 tiny magnets added to each side of the flywheel. Oil and water temps would have a few options, some as simple as using JB-Weld to bond the sensors to the hot and cold sides of the oil cooler. In those cases the values would be more for comparison and getting a baseline since they would not be accurate.

Total price for the board and a few sensors would be less than $100 and you'd get it all from Amazon.

Base board:

http://www.amazon.com/arduino-org-A...e=UTF8&qid=1450373441&sr=8-2&keywords=arduino

Temp sensors (5 for $12):

http://www.amazon.com/Vktech-DS18b2...78&sr=8-1&keywords=arduino+temperature+sensor

Tach sensor:

http://www.amazon.com/SainSmart-Eff...73556&sr=8-1&keywords=arduino+magnetic+sensor

EGT Sensor:

http://www.amazon.com/SainSmart-MAX...50373612&sr=8-1&keywords=arduino+thermocouple