funangler

Senior Member

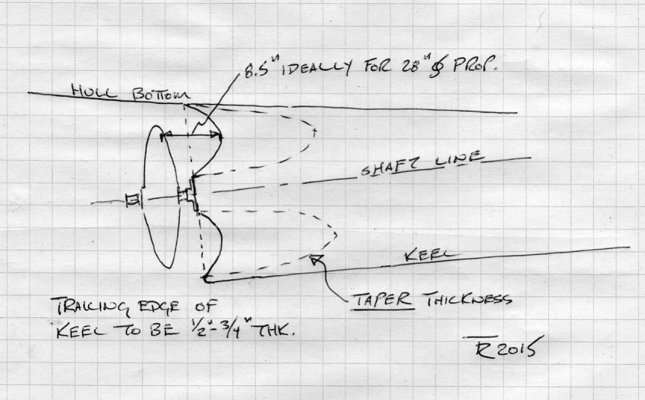

Would you cut the steel out and make it a tapered return to the prop. I find I have a lot more prop noise and vibration above 600 rpm prop speed on the stern. I think the prop is starving for water. It would probably takes four days to cut it,shape it, and repaint it. Do you think it is worth it? Prop looks good and so does the cutlass bearing. I have not pulled the shaft.