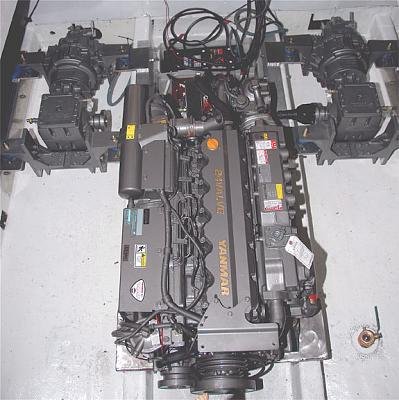

This one looks very similar to the one I mentioned. The write up suggests that the engines can be combined, so I guess there is a way to run both and not get into synchronisation challenges. (Although they are the same model of engine.)

Yes. They're both Grieg class Romsdahl vessels, 65 ft.

I would tend to think that minor synchronization will be adjusted by the

engine governors as they supply fuel according to load. Set the governor on

one engine to rpm, then advance the second to approximately same rpm.

As power is increased on one the other should reduce. The belt system maintaining matching rpm.

The engines have in-out pto type clutches that are operated at the clutch.

Propeller is full reversible controllable pitch.

The owner runs at about 1250 rpm.

Ted