- Joined

- Apr 15, 2008

- Messages

- 13,731

- Location

- California Delta

- Vessel Name

- FlyWright

- Vessel Make

- 1977 Marshall Californian 34 LRC

I recently flushed my port engine with Barnacle Buster and in the process, found an eroded RW outlet elbow. I replaced it with one I bought 5 years ago when I replaced my stbd manifold but didn't need it.

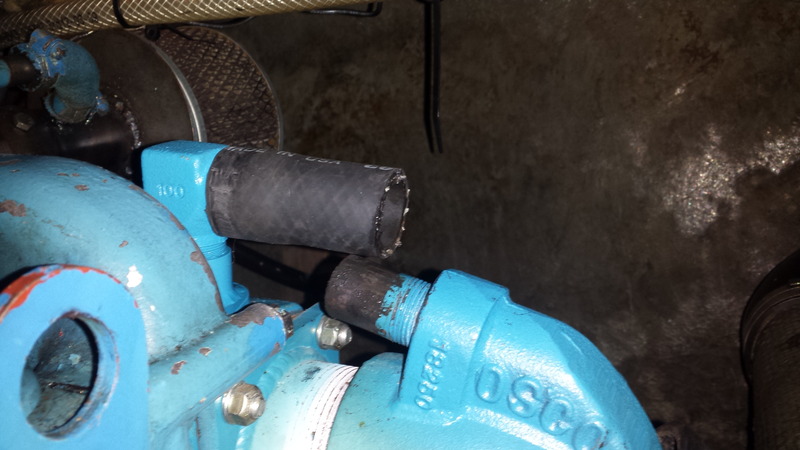

Here's the cast replacement that I installed on the port side.

A few weeks ago, I flushed the RW side of my stbd cooling system and found the elbow needed replacement. Since I had already used my spare for the port side, I ordered a new one from Trans Atlantic Diesel. This one wasn't cast like the original. It was made from a flange with a 90 elbow threaded into it. It sits almost an inch taller making it impossible to line up the short 4-5 inch hose with a 1 inch drop.

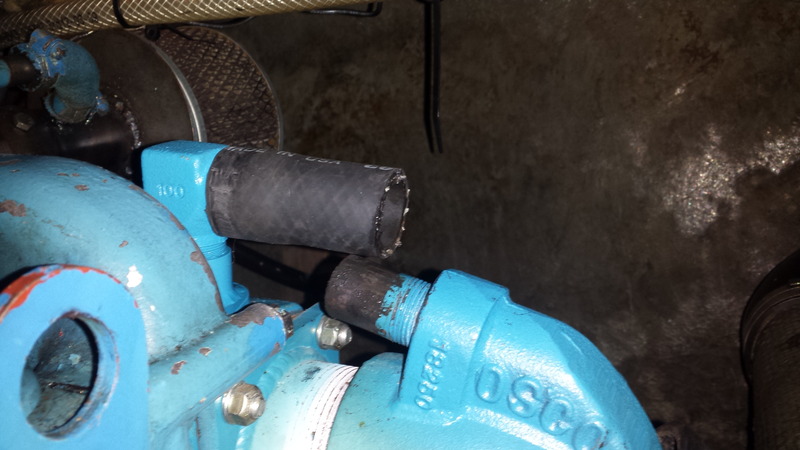

Here's what the stbd one looked like when I pulled it.

Here's how the new one aligns with the mixing elbow.

Since the original cast elbow sat on a 3/4 inch spacer to align the fittings, I used the spacer with my tall fitting to make it even taller. This allowed me to use a new length of 1 in hose to make a 360 degree loop back to the mixing elbow. It's working, but I don't like it. I'd really like to find a cast elbow to install without the looped hose.

When I called TAD asking about a cast unit, they told me they're no longer being made and that's why they are making this style. I tried to find a shaped hose to fit. I tried Napa Auto Parts for a formed hose in 1 inch diameter but no luck.

Does anyone out there have a spare RW outlet elbow they'd be willing to part with or know of a source for a cast one? I'm also considering bringing my old cast elbow to the machine shop for a weld repair, ream and clean up so I can put it back in service. Not sure if there's enough good material for a weld repair, though. I'd rather buy new.

Any thoughts or recommendations? Maybe a source for shaped hose in a 1 inch diameter?

Many thanks for your ideas and advice.

Here's the cast replacement that I installed on the port side.

A few weeks ago, I flushed the RW side of my stbd cooling system and found the elbow needed replacement. Since I had already used my spare for the port side, I ordered a new one from Trans Atlantic Diesel. This one wasn't cast like the original. It was made from a flange with a 90 elbow threaded into it. It sits almost an inch taller making it impossible to line up the short 4-5 inch hose with a 1 inch drop.

Here's what the stbd one looked like when I pulled it.

Here's how the new one aligns with the mixing elbow.

Since the original cast elbow sat on a 3/4 inch spacer to align the fittings, I used the spacer with my tall fitting to make it even taller. This allowed me to use a new length of 1 in hose to make a 360 degree loop back to the mixing elbow. It's working, but I don't like it. I'd really like to find a cast elbow to install without the looped hose.

When I called TAD asking about a cast unit, they told me they're no longer being made and that's why they are making this style. I tried to find a shaped hose to fit. I tried Napa Auto Parts for a formed hose in 1 inch diameter but no luck.

Does anyone out there have a spare RW outlet elbow they'd be willing to part with or know of a source for a cast one? I'm also considering bringing my old cast elbow to the machine shop for a weld repair, ream and clean up so I can put it back in service. Not sure if there's enough good material for a weld repair, though. I'd rather buy new.

Any thoughts or recommendations? Maybe a source for shaped hose in a 1 inch diameter?

Many thanks for your ideas and advice.

Last edited: