skipperdude

Guru

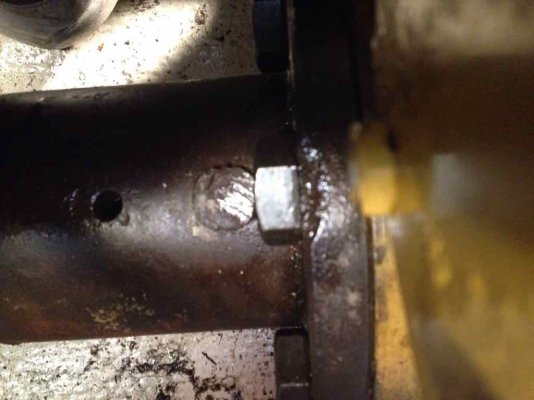

I have to remove the shaft coupler to replace the hose on my stuffing box hose on my stuffing box the bolt that goes through the coupler andshaft have been ground off and mushroomed

The question. is this bolt just threaded it on one end or is it a pin. I'm going to have to drill it out in order to get the coupling off. I can see about a half a thread on the opposite Side of the coupler

The question. is this bolt just threaded it on one end or is it a pin. I'm going to have to drill it out in order to get the coupling off. I can see about a half a thread on the opposite Side of the coupler

The question. is this bolt just threaded it on one end or is it a pin. I'm going to have to drill it out in order to get the coupling off. I can see about a half a thread on the opposite Side of the coupler

The question. is this bolt just threaded it on one end or is it a pin. I'm going to have to drill it out in order to get the coupling off. I can see about a half a thread on the opposite Side of the coupler