She-Kon

Senior Member

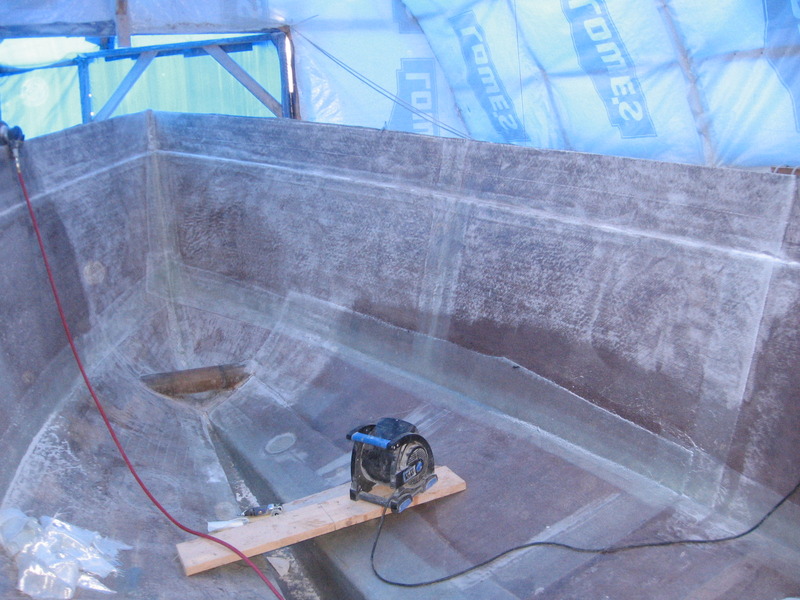

Son of a Bubble!

Fixed that lil' b*stard! Sat there and watched it growing from about 3" across to 6" before I nailed it with the bubble buster.

Sat there and watched it growing from about 3" across to 6" before I nailed it with the bubble buster.

Got the glass for the transom laid up and trimmed but the carpal tunnel syndrome kicked up again. My hands are Sore! Sore! Sore!

M/V She:Kon: Son of a Bubble

There's always tomorrow.

Standby...

Fixed that lil' b*stard!

Got the glass for the transom laid up and trimmed but the carpal tunnel syndrome kicked up again. My hands are Sore! Sore! Sore!

M/V She:Kon: Son of a Bubble

There's always tomorrow.

Standby...