Crusty Chief

Guru

Spent a month on the boat and did a little canvas upgrade. I had a few local canvas shops quote out the job and was not surprised as the prices, 11K to 14 K. the big problem was when they could get to it. Late November and December or later.

So, I decided to do the job myself. I had done canvas work up on Whidbey Island many years ago while in the Navy. It was a great experiance and like riding a bike, you kind of get back into it fairly quickly.

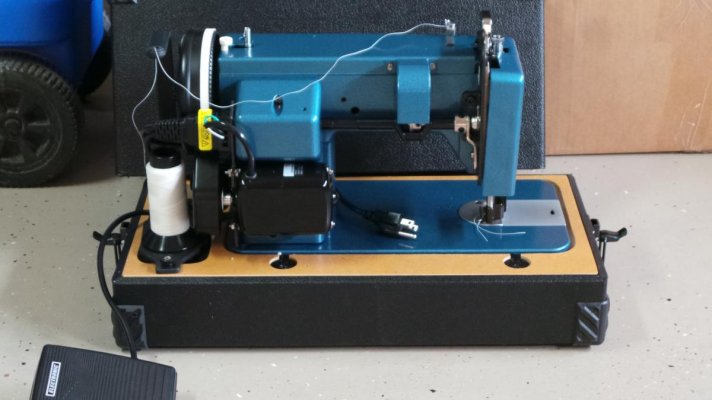

I bought a new Sailrite LZ1 from sailrite and a few attachments, had it shipped to my home here in Las Vegas. Contacted Vaugh bros. in Portland to negotiate pricing and headed North to start work on the Canvas along with other projects.

This is the machine.

So, I decided to do the job myself. I had done canvas work up on Whidbey Island many years ago while in the Navy. It was a great experiance and like riding a bike, you kind of get back into it fairly quickly.

I bought a new Sailrite LZ1 from sailrite and a few attachments, had it shipped to my home here in Las Vegas. Contacted Vaugh bros. in Portland to negotiate pricing and headed North to start work on the Canvas along with other projects.

This is the machine.