cardude01

Guru

- Joined

- Nov 26, 2012

- Messages

- 5,290

- Location

- USA

- Vessel Name

- Bijou

- Vessel Make

- 2008 Island Packet PY/SP

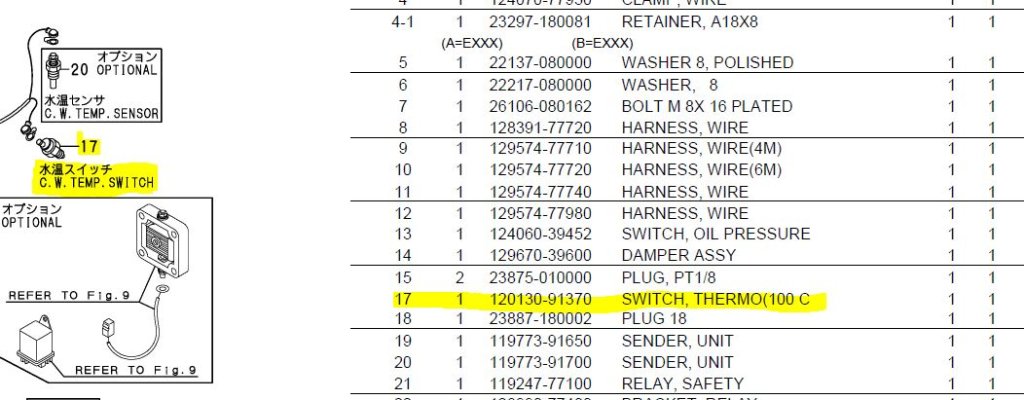

My boat possibly has a little bit of an overheating problem if I push it over 2800 rpm. Engine max rpm is 3200 on the Yanmar 4JH4-hte. I rarely go over 2400 rpm but when passing barges sometimes I need to. I ignored the problem until I got it to the dock here in Texas, but it's here now so...

Anyway, I say "possibly overheating" because the temp taken with the heat gun at the head never seems to match my gauge. It's always about 10 degrees lower with the heat gun.

So maybe I don't have an overheating problem after all? (Hope hope. Wish wish). The heat exchanger access is not good. ?

Or, is the creeping up of the temp more of an indication of overheating?

At what temp do I do damage and crack a head (or whatever breaks on these little engines)?

What temps should the various engine components read with the IR thermometer?

I seem to be Question Man today!

Anyway, I say "possibly overheating" because the temp taken with the heat gun at the head never seems to match my gauge. It's always about 10 degrees lower with the heat gun.

So maybe I don't have an overheating problem after all? (Hope hope. Wish wish). The heat exchanger access is not good. ?

Or, is the creeping up of the temp more of an indication of overheating?

At what temp do I do damage and crack a head (or whatever breaks on these little engines)?

What temps should the various engine components read with the IR thermometer?

I seem to be Question Man today!