Hate to post a discouraging word regarding the Cruise RO Watermaker, but in my opinion, it has a few warts. I bought one of their 30GPH kits two months ago, and am in mid-install as we speak.

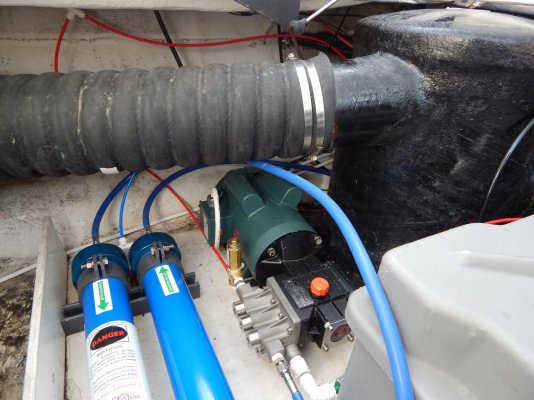

a. Regarding the system design, the provided boost pump is a constant displacement pump. The Shurflo pump supplied requires a bypass to prevent damage to the pump in the event >10psi head is applied to the discharge. In other words, should the operator either over-clamp the discharge, or the down-stream filters become plugged, this pump must vent excess pressure back to the intake side of the pump. This is accomplished in the provided hardware with a check valve between the discharge and intake of the pump, with a cracking pressure of 11psi. It is plumbed with the Mur-Lok fittings Cruise RO is so fond of, and is (again IMHO) not very professionally done. Several very competent boatwrights have looked at the pump and piping and agreed it was not to their liking.

b. The supplied Shurflo pump is NOT rated continuous duty as supplied by Shurflow. It comes from Cruise RO with an acrylic mounted fan to supply cooling air, to help it live. Not impressed.

c. The common solution by most other watermaker vendors is to use a centrifugal pump, installed below the waterline, and rated continuous duty. There are LOTS of these, which easily supply the flow and pressure at the high pressure pump required to prevent HP pump damage. They are self-regulating regarding both pressure and volume. Given a centrifugal with sufficient capacity, when over-clamped, they hum along nicely, even with no flow. Cruise RO's response to this issue is to claim they have at least 20 pumps lying in their shop that have failed this application, and their's is the only solution that works. Huh.

d. The as-supplied design does NOT meet ABYC recommendations for below-the-waterline connections to through-hulls. ABYC recommends vinyl or rubber fiber-reinforced hose, double-clamped to a barbed fitting on the through-hull, for all components below the waterline. ABYC specifically discourages (and, for USCG classification, the CFRs ban) plastic fittings in this application. As most of us do not operate classed vessels, the CG won't care during a routine safety inspection. However, should the vessel suffer water intrusion caused by a plastic fitting (other than Marelon) below the waterline, you betcha your insurance surveyor will care, and possibly deny your claim if so equipped.

e. GA Murdock Inc, the supplier of the Mur-Lok fittings used in the Cruise RO watermaker kit, will NOT sell retail. The only retail vendor they provided to me over the phone does not stock a particular fitting I need to finish my install, nor did Cruise RO. Cruise RO offered to special order this fitting from GA Murdock, with a minimum order of 10 units. Not sure what to do with 9 spares... My pre-purchase inquiry to Cruise RO, asking about the availability of aftermarket Mur-Lok fittings should an issue occur during the install, or later somewhere in the boonies for a repair, was met with the response that they provided "everything" needed make the original install, and some spares as well. Maybe, if you're willing to accept a butch job.

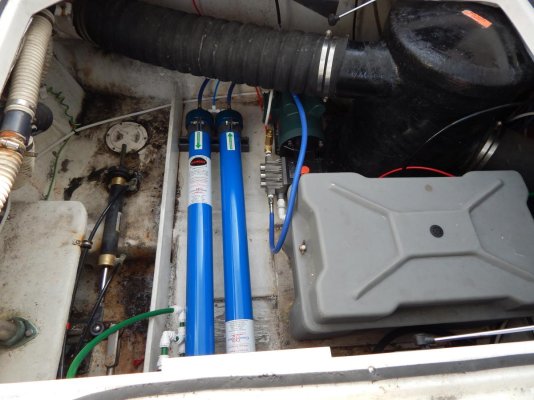

f. Modular watermakers are, by definition, custom installations. Yet this one comes pre-plumbed with these Mur-Lok fittings, with some limited spares provided. Attempts to re-plumb to fit my particular installation required removal of many of the pre-plumbed fittings, salvaging the needed fittings from other parts of the kit, and (in the case of the below-the-waterline fittings) re-plumbing with conventional bronze pipe fittings and reinforced hose. It would be MUCH less time consuming to install this thing if the major components were supplied bare, so the existing plumbing doesn't have to be removed prior to plumbing it to fit each install.

The basic parts (osmotic membranes and housings, HP pump, panels, etc.) are fine. "Some assembly required" is an understatement, but that's installation-specific. The cost of the kit is competitive, but no screaming bargain, given the re-work required to make the thing fit and work. And I'm not real impressed with the whole Mur-Lok fitting gig. Every marine supply house ON THE PLANET stocks barbs, hose, and hose clamps. Mur-Lok? Not.

All of this is, of course, my opinion. I'm not one to butch up an install of anything, simply for expedience. I've been at this yachting hobby many, many years, and have a pretty good professional background in this hydraulics stuff as well. Would I recommend this company to others? Yes, with MANY caveats. Would I buy another from Cruise RO? Nope, I'd simply multiple-source the components, and build my own. YMMV.

Regards,

Pete