No Mast

Guru

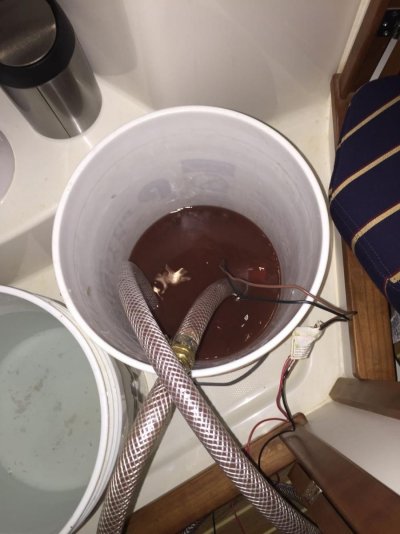

One of our AC units has started shutting down with a high pressure error code. It'll run for a while, then shut down. Besides backwashing the unit, which we've already tried, is there anything else we can do before we have to pay someone else to fix it?