Hi All, I'm a newbe so i'm not familiar with the protocol here but feel I have some useful information concerning vaccume gages and fuel filters. We all know the gage is normally used to indicate the condition of the element in the primary filter. If you have seen the Racor vaccume gage you notice the scale is color coded green-yellow-red, the implications being obvious. However it is a one size fits all solution and requires a good bit of guess work. The simple reason is because every boat has different supply plumbing and is of different age. Every component ,fitting, hose etc. in the fuel delivery system between the tank supply tube and the fuel lift pump causes a restriction the pump must overcome. The pump can only develop so much vaccume and when there is too much restriction the fuel flow stops. We need to know when our specific fuel system is getting ready to shut down or better yet well befor. The filter elements will cut off fuel flow when the resistance through the element reaches 7" of vaccume. A new element will generally show a 1"-2" vaccume reading on the gage. So when the gage reads 8"-9" the flow will most likely have stopped indicating the element has reached the very end of its life span. For obvious reasons you don't want to go that far. Change the element when the reading is one or two inches lower. All this applies regardless of the micron rating of the element as the gage is simply measuring the results of restriction to flow. I mentioned age befor and it is important because an old lift pump may not be able to develop its maximum rated vaccume and as such fuel flow may stop at a lower point. You end up changing elements earlier or better yet replace the pump. The vaccume can be checked at any RPM but it may be more stable at a speed off of idle. Once you have your specific set of numbers the decision about when to change elements is pretty much cut and dry. After looking at the old elements you can decide if necessary to lengthen or shorten the run time. An easy way to get an idea as to the condition of the elements while under way is to run to full RPM. If the RPM comes up to max then all is good. My choice is to do this at the end of the day. Personally I really dislike having to change an element 1 hour into the days run. It really ruins that second cup of coffee.* The gage used is up to you as they all read the same thing, however try to get one with an easy to read scale. The basic Racor gage is fine but the usual location is poor. Better to buy the Racor adptor that screws into the engine side of the filter body and allows running tubing to wherever you want the gage. The 1/8" plastic tubing used for ice makers an brass fittings work great and are easy to install. Be sure to buy a gage with 1/8" connection to keep things simple. You do need to be careful to make good tight connections as an air leak will shut down the engine rather quickly. Hope this helps. Gotta run but will get to filters next time. Trader

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vaccume gages and filters

- Thread starter trader

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

sunchaser

Guru

- Joined

- Apr 9, 2008

- Messages

- 10,195

- Location

- usa

- Vessel Name

- sunchaser V

- Vessel Make

- DeFever 48 (sold)

Why does your gauge show "high"vacuum? Are you sucking fuel uphill or 50 gph while recycling 45 gph? If not, with the right filters, good fuel*and clean tanks on our small trawler motors, an "increasing" vacuum gauge reading points to a fundamental flaw somewhere you better get fixed. My Racor gauges always read 0 -*I do close off the*fuel valves on occasion to check that the gauges are working.

-- Edited by sunchaser on Friday 31st of December 2010 12:13:28 PM

-- Edited by sunchaser on Friday 31st of December 2010 12:13:28 PM

The vacuum gauges in the fuel lines of low-flow engines like the FL120 never go above "0" unless there is a restriction in the line or the filter element is getting clogged. Everyone I know with a boat with these types of engines and a vacuum gauge changes the filter when the vacuum reading is anything other than "0." The marks and color bands are meaningless in this application--- the only meaningful clue is if the needle isn't on "0." We always change our Racor elements when we change the engine oil, so every 100 to 150 hours. We have had the gauges on our filters for some six or seven years now, and they have never read anything but "0." And yes, we have tested the gauges to make sure they work.

jleonard

Guru

- Joined

- Jun 25, 2008

- Messages

- 5,063

The vacuum gage on my FL120 read at about 5 or 6 when my engine would shut down. That was on my maiden delivery voyage (and if you think 12 elements are enough for a 500 mile trip, not always).

Since I replaced the lift pump and changed from 2 micron filters to multistage I have never seen over 1. One gage (on the 30 micron Racor) reads 0, one gage reads close to 1 (on the 10 micron Racor) when new.

Since I replaced the lift pump and changed from 2 micron filters to multistage I have never seen over 1. One gage (on the 30 micron Racor) reads 0, one gage reads close to 1 (on the 10 micron Racor) when new.

The fundamental flaw is a dock side committee passing on flawed information based on a fundamental lack of understanding of the fundamental basic fluid and filter flow dynamics, a fundamental lack of understanding of basic analog gage operational parameters and most embarrassing of all, not being able to understand that if there is O vacuum at the Racor there is O fuel flow. Rearranging facts to fit ones opinion doesn't make the facts incorrect. TRADER

RickB

Guru

- Joined

- Oct 20, 2007

- Messages

- 3,804

- Vessel Make

- CHB 48 Zodiac YL 4.2

Are you the self appointed head of that committee or just wake up and decide to make 2011 the year of the ass?trader wrote:The fundamental flaw is a dock side committee passing on flawed information based on a fundamental lack of understanding of the fundamental basic fluid and filter flow dynamics, a fundamental lack of understanding of basic analog gage operational parameters and most embarrassing of all, not being able to understand that if there is O vacuum at the Racor there is O fuel flow.

If the level of fuel in the tank in service is higher than the filter then there is a positive static head. If the lift pump is at or below the level of the filter then there is a positive static head at the pump as well. When the engine is running there will be a slight pressure differential created by the filter element and friction in the fuel lines but in most cases it is not enough to move a bourdon tube gauge off the peg unless the element is very dirty.

*

Are you the self appointed head of that committee or just wake up and decide to make 2011 the year of the ass?RickB wrote:

trader wrote:The fundamental flaw is a dock side committee passing on flawed information based on a fundamental lack of understanding of the fundamental basic fluid and filter flow dynamics, a fundamental lack of understanding of basic analog gage operational parameters and most embarrassing of all, not being able to understand that if there is O vacuum at the Racor there is O fuel flow.

If the level of fuel in the tank in service is higher than the filter then there is a positive static head. If the lift pump is at or below the level of the filter then there is a positive static head at the pump as well. When the engine is running there will be a slight pressure differential created by the filter element and friction in the fuel lines but in most cases it is not enough to move a bourdon tube gauge off the peg unless the element is very dirty.

*

Rick,

Well "fundamentally" said!

El Sea/ L.C.

*

sunchaser

Guru

- Joined

- Apr 9, 2008

- Messages

- 10,195

- Location

- usa

- Vessel Name

- sunchaser V

- Vessel Make

- DeFever 48 (sold)

Dear Trader

Welcome to the Forum. You have joined an elite crowd. Someof us actually have boats, unlike other Forums where landlubbers opine regularly. Some of us in fact have an educational and experience background where fluid dynamics are a way of life. Personally I am on this Forum to escape the drudgery of work issues such as shear thinning, apparent vs actual viscosity*and Pascals. For fear that some person much smarter than me is lurking nearby, I try not to let too much of my ammo show.

My situation is as RickB suggested, with Racors* positioned* below my nominal fuel tank level. I indeed have static positive pressure at the Racor gauge, approximately* 1.5 whopping psi.

Tell us about your boat, we'd love to hear more.

Welcome to the Forum. You have joined an elite crowd. Someof us actually have boats, unlike other Forums where landlubbers opine regularly. Some of us in fact have an educational and experience background where fluid dynamics are a way of life. Personally I am on this Forum to escape the drudgery of work issues such as shear thinning, apparent vs actual viscosity*and Pascals. For fear that some person much smarter than me is lurking nearby, I try not to let too much of my ammo show.

My situation is as RickB suggested, with Racors* positioned* below my nominal fuel tank level. I indeed have static positive pressure at the Racor gauge, approximately* 1.5 whopping psi.

Tell us about your boat, we'd love to hear more.

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

To me the problems are ,

1. there is only one filter so it will have to be changed , rather than a lever simply thrown.

2. its in the engine room, do you really want to be down there bouncing off a dead engine attempting to change the element , fill the filter and perhaps bleed the engine?

3. Hose , even USCG fuel hose is cheap , I would get a pair of whatever your favorite filters are , and a pair of lever operated fuel OK ball valves and move it OUT of the engine spaces to a spot you can see them, drain them and as required replace the elements .

1. there is only one filter so it will have to be changed , rather than a lever simply thrown.

2. its in the engine room, do you really want to be down there bouncing off a dead engine attempting to change the element , fill the filter and perhaps bleed the engine?

3. Hose , even USCG fuel hose is cheap , I would get a pair of whatever your favorite filters are , and a pair of lever operated fuel OK ball valves and move it OUT of the engine spaces to a spot you can see them, drain them and as required replace the elements .

sunchaser

Guru

- Joined

- Apr 9, 2008

- Messages

- 10,195

- Location

- usa

- Vessel Name

- sunchaser V

- Vessel Make

- DeFever 48 (sold)

Carl

Your reading is identical to mine with engines running.

Unless you have old dirty tanks and a history of clogging filters, I'd ignore the need for a second filter as FF suggests - nice to have though. Moving the filters outside the*ER is not necessary as FF suggests and seems silly for a 2 gph Lehman or a*75 gph MAN for that matter. I'd be curious to know how many have their primary filters removed from the ER space - very few I betcha. As for the hoses, yes use the right stuff if you are not already.

Your reading is identical to mine with engines running.

Unless you have old dirty tanks and a history of clogging filters, I'd ignore the need for a second filter as FF suggests - nice to have though. Moving the filters outside the*ER is not necessary as FF suggests and seems silly for a 2 gph Lehman or a*75 gph MAN for that matter. I'd be curious to know how many have their primary filters removed from the ER space - very few I betcha. As for the hoses, yes use the right stuff if you are not already.

C lectric

Guru

With low or no vacuum the needle will point to ~05:00 which is where yours is. That's where vacuum guages rest.

With the engine running and clean filters that's where you want to see it or as close as possible.

As the filter plugs, the vacuum rises, the needle will rotate counterclockwise.

Aside from adding filters and such, one easy and inexpensive improvement that could be made is to get a guage with a telltale, second needle, which will stay at the highest point of vacuum reached while running. That way you can check later, after the engine is shutdown, to get a warning of filter clogging. You do not need to look at the guage while running. The guage you have now, without the telltale, must be observed while running to get a reading.

With the engine running and clean filters that's where you want to see it or as close as possible.

As the filter plugs, the vacuum rises, the needle will rotate counterclockwise.

Aside from adding filters and such, one easy and inexpensive improvement that could be made is to get a guage with a telltale, second needle, which will stay at the highest point of vacuum reached while running. That way you can check later, after the engine is shutdown, to get a warning of filter clogging. You do not need to look at the guage while running. The guage you have now, without the telltale, must be observed while running to get a reading.

trader wrote:

The fundamental flaw is a dock side committee passing on flawed information based on a fundamental lack of understanding of the fundamental basic fluid and filter flow most embarrassing of all, not being able to understand that if there is O vacuum at the Racor there is O fuel flow. Rearranging facts to fit ones opinion doesn't make the facts incorrect.

The above was obviously written by someone with minimal experience with boats and marine powerplants. I can think of no other explanation unless the fact that our two FL120s run just great with the Racor vacuum gauges on top of the filters sitting on zero is a fantasy and we are in fact sitting in our slip with dead engines instead of cruising through the islands. I also have to assume that the identical experience of everyone I know with an FL120-powered boat and vacuum gauges is also a fantasy.

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

"and I have run up the coast with her with no problem, "

Its NOT the "no problem" runs a fuel filtering system is designed or located for.

Its the sound of silence that a good system is designed to prevent , or at worst cure.

Its NOT the "no problem" runs a fuel filtering system is designed or located for.

Its the sound of silence that a good system is designed to prevent , or at worst cure.

- Joined

- Jun 25, 2008

- Messages

- 10,104

- Location

- Australia

- Vessel Name

- Now boatless - sold 6/2018

- Vessel Make

- Had a Clipper (CHB) 34

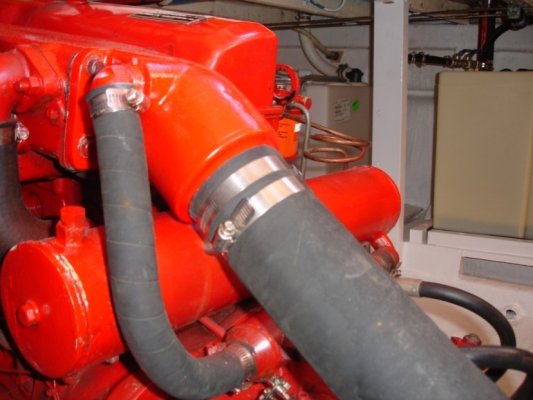

Slightly off topic, but stimulated by the pic of the big red engine (120 Lehman, same as mine) in the original post, when I went to check the engine levels and top up as required before heading out last weekend, I noticed a drip from the port end of the oil cooler/heat exchanger, and when I fired her up, two jets of water squirted out from the end join. Needless to say that kiboshed our new year short cruise to watch the fireworks etc.

I presume the gasket has gone in that end, but what are we likely to find when the diesel mechanic pulls it apart. I am preparing myself for the worst - possibly a new unit - as it looks rather corroded round that end, even tho it is bonded through attachment to the engine - or so I thought. I think the zincs were done when the main engine heat exchanger above it was re-conditioned ~ 2 yrs ago. How often should these zincs be changed....? I guess that would be a time thing, rather than an engine hours thing..?

I presume the gasket has gone in that end, but what are we likely to find when the diesel mechanic pulls it apart. I am preparing myself for the worst - possibly a new unit - as it looks rather corroded round that end, even tho it is bonded through attachment to the engine - or so I thought. I think the zincs were done when the main engine heat exchanger above it was re-conditioned ~ 2 yrs ago. How often should these zincs be changed....? I guess that would be a time thing, rather than an engine hours thing..?

JohnP

Guru

- Joined

- Dec 13, 2009

- Messages

- 1,361

- Location

- USA

- Vessel Name

- V E N T U R E

- Vessel Make

- 1996 36' Island Gypsy Classic

Peter B wrote:

Slightly off topic, but stimulated by the pic of the big red engine (120 Lehman, same as mine) in the original post, when I went to check the engine levels and top up as required before heading out last weekend, I noticed a drip from the port end of the oil cooler/heat exchanger, and when I fired her up, two jets of water squirted out from the end join. Needless to say that kiboshed our new year short cruise to watch the fireworks etc.

I presume the gasket has gone in that end, but what are we likely to find when the diesel mechanic pulls it apart. I am preparing myself for the worst - possibly a new unit - as it looks rather corroded round that end, even tho it is bonded through attachment to the engine - or so I thought. I think the zincs were done when the main engine heat exchanger above it was re-conditioned ~ 2 yrs ago. How often should these zincs be changed....? I guess that would be a time thing, rather than an engine hours thing..?

If you are talking about the engines heat exchanger, replacing the end gaskets and cleaning up the end plates will probably stop the leak.

If one of the oil coolers is leaking I think I would get a new one. There is one for your engine for 79. dollars on Ebay.* Type in Ford Lehman 120 and it will appear the seller is FredWerner, I have purchased an exhaust elbow from him and he is an honest seller.

If you open the main heatexchanger it is a good time to flush it out, The zinc should be changed at least once a year.

These engines are easy to maintain.* Hope that helps

*

Attachments

O C Diver

Guru

- Joined

- Dec 16, 2010

- Messages

- 12,867

- Location

- USA

- Vessel Name

- Slow Hand

- Vessel Make

- Cherubini Independence 45

Peter, transmission coolers have soldered end caps (no gaskets). I have had one resoldered at a radiator shop. It lasted about 3 months and then started leaking again. The lead in the solder gets eaten away just like a zinc. Removing the end cap, cleaning both surfaces and resoldering is the only way to get a good seal. Unfortunately it takes real skill to resolder it without disturbing the solder on the internal tube bundle. Buy a new one as a used one will give you no idea of the life expectancy of the solder.Peter B wrote:

Slightly off topic, but stimulated by the pic of the big red engine (120 Lehman, same as mine) in the original post, when I went to check the engine levels and top up as required before heading out last weekend, I noticed a drip from the port end of the oil cooler/heat exchanger, and when I fired her up, two jets of water squirted out from the end join. Needless to say that kiboshed our new year short cruise to watch the fireworks etc.

I presume the gasket has gone in that end, but what are we likely to find when the diesel mechanic pulls it apart. I am preparing myself for the worst - possibly a new unit - as it looks rather corroded round that end, even tho it is bonded through attachment to the engine - or so I thought. I think the zincs were done when the main engine heat exchanger above it was re-conditioned ~ 2 yrs ago. How often should these zincs be changed....? I guess that would be a time thing, rather than an engine hours thing..?

Ted

*

RickB

Guru

- Joined

- Oct 20, 2007

- Messages

- 3,804

- Vessel Make

- CHB 48 Zodiac YL 4.2

FF wrote:* "I would get a pair of whatever your favorite filters are , and a pair of lever operated fuel OK ball valves and move it OUT of the engine spaces to a spot you can see them, drain them and as required replace the elements ."Baker wrote:...and folks, I think FF was talking about putting the GAUGE outside of the engine room....not the whole filter assembly.

Not that there is anything wrong with that if you have the space to dedicate to fuel management.

*

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

".and folks, I think FF was talking about putting the GAUGE outside of the engine room....not the whole filter assembly."

A remote reading DP (differential pressure ) gauge with alarm (murphygages) is better than an Engine room crawl to see a stuck on top vacume gauge..

And yes the filters as well as fuel tank selection are far better and easier to service OUT of the engine room.

A remote reading DP (differential pressure ) gauge with alarm (murphygages) is better than an Engine room crawl to see a stuck on top vacume gauge..

And yes the filters as well as fuel tank selection are far better and easier to service OUT of the engine room.

- Joined

- Jun 25, 2008

- Messages

- 10,104

- Location

- Australia

- Vessel Name

- Now boatless - sold 6/2018

- Vessel Make

- Had a Clipper (CHB) 34

Peter, transmission coolers have soldered end caps (no gaskets). I have had one resoldered at a radiator shop. It lasted about 3 months and then started leaking again. The lead in the solder gets eaten away just like a zinc. Removing the end cap, cleaning both surfaces and resoldering is the only way to get a good seal. Unfortunately it takes real skill to resolder it without disturbing the solder on the internal tube bundle. Buy a new one as a used one will give you no idea of the life expectancy of the solder.O C Diver wrote:Peter B wrote:

Slightly off topic, but stimulated by the pic of the big red engine (120 Lehman, same as mine) in the original post, when I went to check the engine levels and top up as required before heading out last weekend, I noticed a drip from the port end of the oil cooler/heat exchanger, and when I fired her up, two jets of water squirted out from the end join. Needless to say that kiboshed our new year short cruise to watch the fireworks etc.

I presume the gasket has gone in that end, but what are we likely to find when the diesel mechanic pulls it apart. I am preparing myself for the worst - possibly a new unit - as it looks rather corroded round that end, even tho it is bonded through attachment to the engine - or so I thought. I think the zincs were done when the main engine heat exchanger above it was re-conditioned ~ 2 yrs ago. How often should these zincs be changed....? I guess that would be a time thing, rather than an engine hours thing..?

Ted

Thanks Ted.* having found my saved copy of the Lehman manual finally, I see they actually recommend replacement at about 3 yrly intervals, and your soldered ends description fits what it looks like exactly, so yes - a new unit coming up I suspect, and that probably means a new one for the engine oil as well, as they appear to be similar units, and it is no doubt as old as the tranny one which gave way.* Then one wonders about the engine heat exchanger as well - they say clean yrly - replace 5 yrly....this could get ugly.......

*

RT Firefly

Enigma

Hiya,

** Mr. Peter B.* Yes,*I would suspect the life of the zinc is a time thing as well.* When replacing coolers, try to get the cupro/nickel units.* They're supposed to last longer.* Keep in mind, when replacing zincs in these things, do NOT use teflon tape.* Try conductive grease instead.

** Mr. Peter B.* Yes,*I would suspect the life of the zinc is a time thing as well.* When replacing coolers, try to get the cupro/nickel units.* They're supposed to last longer.* Keep in mind, when replacing zincs in these things, do NOT use teflon tape.* Try conductive grease instead.

RickB

Guru

- Joined

- Oct 20, 2007

- Messages

- 3,804

- Vessel Make

- CHB 48 Zodiac YL 4.2

sunchaser wrote:... where outside the ER space would one locate the filters?

*In the purifier room of course!

It wasn't a suggestion to move the filters and valves into the V berth or aft cabin, it was just a comment that crawling between or around hot machinery on a rolling boat to change a filter or look at a gauge is not ideal. An easily accessed location outside the engine room would be ideal*if such a place existed. If it doesn't then the idea doesn't apply.

Providing a remote reading vacuum gauge is very easily done and eliminates half the potential discomfort.

O C Diver

Guru

- Joined

- Dec 16, 2010

- Messages

- 12,867

- Location

- USA

- Vessel Name

- Slow Hand

- Vessel Make

- Cherubini Independence 45

Peter, shop around when you look for the transmission cooler. When I replaced mine last spring, I was able to find an exact match that had a place to drill and tap it for a 3/8" heat exchanger anode. Most factory oil coolers don't seem to have them (go figure). Most heat exchangers have an anode. On Cummins its a hex head brass pipe plug that the anode screws into. I check mine every season, and need to replace it every 2 or 3 years.Peter B wrote:

Thanks Ted. having found my saved copy of the Lehman manual finally, I see they actually recommend replacement at about 3 yrly intervals, and your soldered ends description fits what it looks like exactly, so yes - a new unit coming up I suspect, and that probably means a new one for the engine oil as well, as they appear to be similar units, and it is no doubt as old as the tranny one which gave way. Then one wonders about the engine heat exchanger as well - they say clean yrly - replace 5 yrly....this could get ugly.......

*

*

Ted

*Peter B wrote:

*

........Then one wonders about the engine heat exchanger as well - they say clean yrly - replace 5 yrly....this could get ugly.......

*___________________________________________________________

We have a SeaKamp heat exchanger on our Lehman.* We were told with inspections and proper maintenance it should last 15-20 years.* I think we paid around $500 USD.

http://www.seakamp.com/

*

tgwhite, I am going to be quoting from the Parker Hanninfin Corp (RACOR) installation, operation and service information manual which we have as referance in our shop but probably can be viewed at their website. On page 3 they have plumbing schematics detailing the three most common installations. 1) tank above the level of the filter, 2) tank at same level as filter, 3) tank below level of filter. Locations of both a pressure pump and a pump installed in the vacuum side are included in the drawings. Head pressure is not to exceed 15PSI regardless 1) as a result of tank location, or 2) From a pressure pump. Moving on to page 5, SERVICE INSTRUCTIONS, Element Replacement and I quote, Frequency of element replacement is determined by the contamination level of the fuel. Replace the elements every 10,000 miles, every 500 hours, every other oil change, when the vacuum gauge (optional) reads between 6 to 10 inches of mercury(inHG), if power loss is noticed, or annually, which ever comes first. Note always carry extra replacement elements as one tankful of excessively dirty fuel can plug a filter, end quote. There are no ands ifs or buts with respect to what the filter is used for, the filter doesn't know or care if the fuel is going to a diesel stove, a truck, a VW, a water pump, or a boat. The operation of the filter is the same regardless the engine. Head pressure will extend the life of the element because it is easier for a pump to move a fluid using pressure rather than vacuum. Even with pressure the element fouls to the point the vacuum reading will start to increase as the lift pump is still tryin to draw the fuel to the engine and as I stated in my original post and as the Racor manual indicates when the vacuum reaches a specific range it is time to change elements. Analog gages are the most common type used and they are designed to be accurate at mid scale. The typical vacuum gage has a 0-30 range and therefor is only accurate + or - in the area of 15. A compound gage(reads both pressure and vacuum) Is a good alternative as the 0 on the scale is right in the middle of the scale and therefor the low indications are more likely to show up. The scale usually doesn't exceed 15 so this puts the 6-10 in the middle of the range,also good for accuracy. The whole idea of the vacuum gage is to help the operator get the maximum life out of the elements and provide a simple by the numbers way to decide when to change elements. Detroit Diesel has taken a different route for filter monitoring. They have a filter body with clear bowl that allows a full view of the element and this makes it easy to view the fowling line as it moves up the element. The element in the Racor Turbine series filters can be inspected the same way but must be removed first. TRADER

O C Diver

Guru

- Joined

- Dec 16, 2010

- Messages

- 12,867

- Location

- USA

- Vessel Name

- Slow Hand

- Vessel Make

- Cherubini Independence 45

I'm confused, do you think we don't know how to use and service our fuel seperators / filters?trader wrote:

tgwhite, I am going to be quoting from the Parker Hanninfin Corp (RACOR) installation, operation and service information manual which we have as referance in our shop but probably can be viewed at their website. On page 3 they have plumbing schematics detailing the three most common installations. 1) tank above the level of the filter, 2) tank at same level as filter, 3) tank below level of filter. Locations of both a pressure pump and a pump installed in the vacuum side are included in the drawings. Head pressure is not to exceed 15PSI regardless 1) as a result of tank location, or 2) From a pressure pump. Moving on to page 5, SERVICE INSTRUCTIONS, Element Replacement and I quote, Frequency of element replacement is determined by the contamination level of the fuel. Replace the elements every 10,000 miles, every 500 hours, every other oil change, when the vacuum gauge (optional) reads between 6 to 10 inches of mercury(inHG), if power loss is noticed, or annually, which ever comes first. Note always carry extra replacement elements as one tankful of excessively dirty fuel can plug a filter, end quote. There are no ands ifs or buts with respect to what the filter is used for, the filter doesn't know or care if the fuel is going to a diesel stove, a truck, a VW, a water pump, or a boat. The operation of the filter is the same regardless the engine. Head pressure will extend the life of the element because it is easier for a pump to move a fluid using pressure rather than vacuum. Even with pressure the element fouls to the point the vacuum reading will start to increase as the lift pump is still tryin to draw the fuel to the engine and as I stated in my original post and as the Racor manual indicates when the vacuum reaches a specific range it is time to change elements. Analog gages are the most common type used and they are designed to be accurate at mid scale. The typical vacuum gage has a 0-30 range and therefor is only accurate + or - in the area of 15. A compound gage(reads both pressure and vacuum) Is a good alternative as the 0 on the scale is right in the middle of the scale and therefor the low indications are more likely to show up. The scale usually doesn't exceed 15 so this puts the 6-10 in the middle of the range,also good for accuracy. The whole idea of the vacuum gage is to help the operator get the maximum life out of the elements and provide a simple by the numbers way to decide when to change elements. Detroit Diesel has taken a different route for filter monitoring. They have a filter body with clear bowl that allows a full view of the element and this makes it easy to view the fowling line as it moves up the element. The element in the Racor Turbine series filters can be inspected the same way but must be removed first. TRADER

Ted

*