Pour a nice cuppa joe, as I'm catching up. It's been a long month, and finally I pulled the plug on Carrabelle. With trepidation, sadness, and irritation with my own Project Management skills (or lack thereof) I've bitten the bullet, hired a truck and am now in St. Pete, FL.

This job will be finished.

As a matter of fact, two days ago a mechanic was scheduled to come out but the afternoon thunder-boomers delayed until next week. That's okay -- I've got someone and am happy/hopeful again.

As per the suggestion of AusCan I've got a hard copy of the Beta20 shop manual. I've read it and again this entire thread. Y'all cannot imagine how much I appreciate the wisdom shared.

Especially as I endeavor to finish the bloody job. Finally.

I will of course ask re a couple things.

#1) The stainless -- about the addition of the spacer between the engine and that manifold/whatever. I don't have one, and think that if we keep the stainless the spacer at the engine would go a long way toward preventing stress cracks.

No, the support bracket was not welded in Carrabelle.

Please don't ask.

Looking in the rear view mirror is a recipe for unhappiness. I'm looking forward with joy and anticipating good things coming my way. Including an engine that actually moves the boat.

What a concept, eh?!?

#2) The other, should I simply dispose of the stainless and go with a standard exhaust elbow/salt water injection system as in thousands of boats? That's probably what will happen however I am willing to be persuaded in either direction.

The thing that most concerns me is that I cannot see inside that box. I won't know if there is an issue until it is too late so obviously I'm leaning toward the Norm, versus the new.

Still, I admit to wanting to know if what was designed will work. I'd like to believe it will but that's neither here nor there. Right now I have a boat that won't run.

The gent who used his jet-ski to tow me across the river ("Thanks Freddie") took a gander at the engine. He states four hours and she'll be finished, give or take. That works for me.

And now, for the comments, questions and more as posted of late. I'm catching up. I confess to avoiding the thread while not-a-thing was happening but now? Well, now things are going to move along at a better pace.

I do hope I've learned a hard lesson: don't let time pass by. It's too precious.

If that Beta 20 manual also shows the water pumps, heat exchangers, and exhaust elbows and so forth that they routinely use... it might be giving you a shopping list of parts (and part numbers) for future improvements.

Too true Chris. They have something similar I suspect however instead of mounting where the hot air exhausts, it's lower. It seems to serve the same purpose though.

And I look forward to learning what the local guy here has to say.

No matter what you should see 5000 hours from your setup, at 200 hours a year , thats a lot of years.

The loop is perhaps 1000 hours ,gona do it 5 times?

Now, don't forget about Manatee... they've done the loop more than twenty times. At five knots I'm not going fast anywhere. Still, I intend to have a lot of fun.

Can't wait!

The Beta Marine 20 would be a great engine to emulate in Janice's case, but I am afraid that the cost of marinization parts would be astronomical. The heat exchanger is integral with the jacketed exhaust manifold and as a result is a very expensive part. Such is the nature of marinizing a cheap ubiquitous diesel for a small marine market.

(SNIPPED)

Fresh water flushing. The theory is that flushing out the sea water that lies in the heat exchanger and other raw water parts with fresh water after each use will reduce corrosion. Sea water corrodes bronze and cupronickel tubes much faster than fresh water.

There are a number of ways to do this but let's not get into that right now. Get the engine up and running right first.

My heat exchanger is a separate unit bolted on the forward bulkhead in the engine room.

Amen re getting her up and running first. That's my top priority.

But the real purpose of this discussion was failure of the stainless steel welds in Janice's contraption. SS doesn't last all that long in sea water, especially welds.

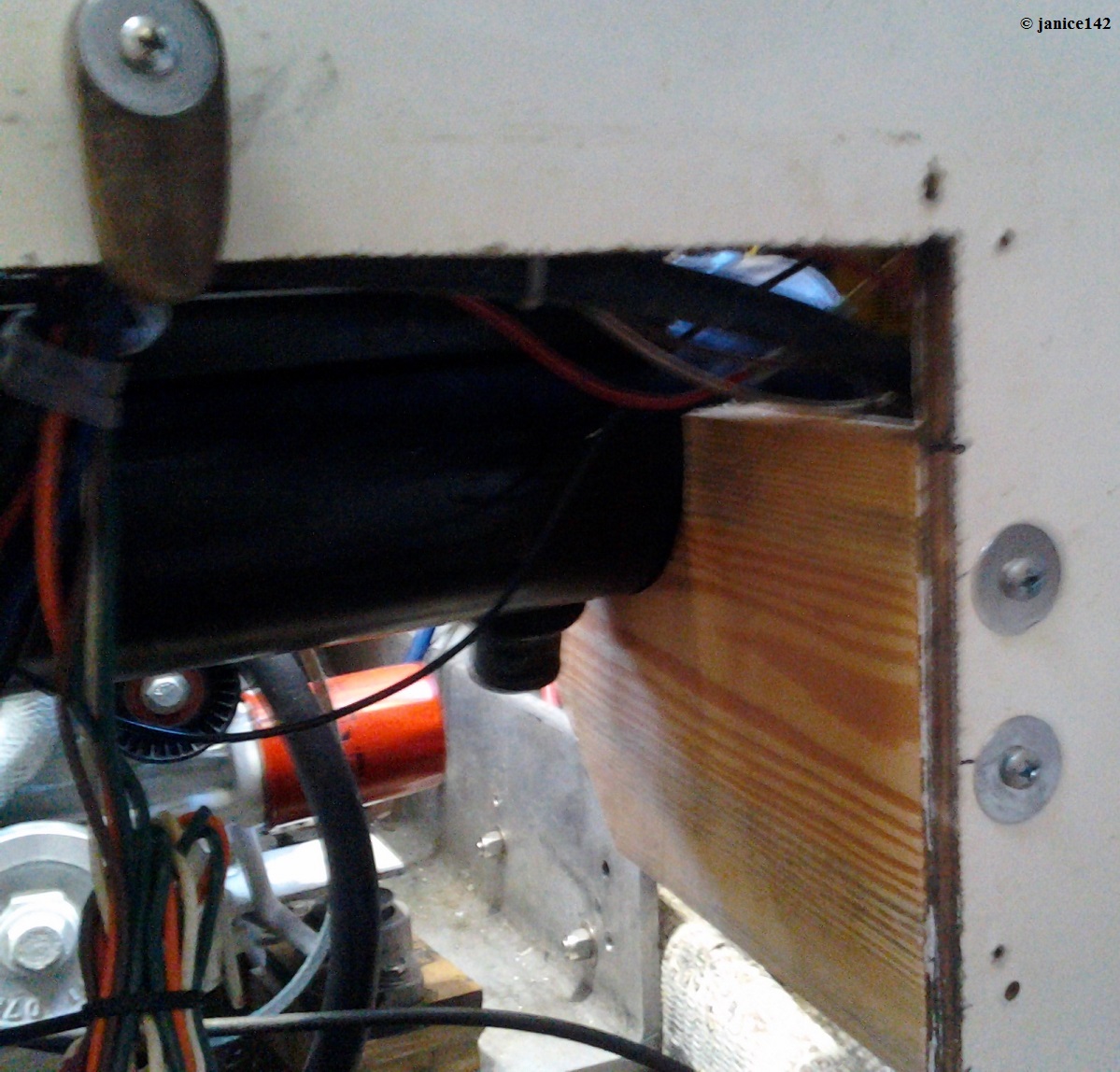

Here's an overhead view:

And yes, I do think the wire-reinforced hose mentioned previously, between the flange on the engine and the stainless is a Necessity. If we keep the stainless.

I installed 'Quick Flush Valves' in Jan this year.

(SNIPPED)

The install of the valve was simpler than expected - didn't even need to cut a hose (got the hose shop to cut me 2 x 2inch long bits). Just undid the raw water hose at outlet side of strainer, push it back a bit, fit one end of flush vave to that, fit one of the 2inch bits on other side and onto the strainer outlet. Literally a 5 minute install.

I bought the optional 'strainer hose' attachment that allows me to draw water out of a bucket. Much safer as damage can be done to engine by plugging water hose directly into the valve without having the motor running. Thought it a much safer option to draw from a bucket with fresh water hose filling bucket. Plus allows additives like salt-away (or glycol for you winterizing folks) to be added easily.

We did something similar on our 40'er. I just didn't remember how so having the name (Quick Flush Valves) is a big help. This in theory ought to be a benefit and being able to watch the water suck up from a bucket is a real boon. Thanks for the information.

A very simple marinization would simply wrap the manifold with proper insulation , and use common pipe for the exhaust , with a pipe water injector in the proper location.

This is the likely Best Choice to make. I will consult with the mechanic when he is on the boat this coming week. I like something I can look at an examine. The hidden injection point on the stainless already has me worried, and it's unused at present.

I've been following your trials and tribulations with some interest. I wonder how, or if, things have been resolved?

The "solution" was to get out of Carrabelle. Sunday night my friend Kim spotted Seaweed across the river at the boatyard ready for hauling on Monday morning. Like many she did not realize the extent of my unhappiness. Nor how long it had been.

Now on to the net phase: i.e. getting her running again. I was sorry to pay $$ to get out of Carrabelle, however too many disappointments and no-shows... well, at a certain point the towel is throw in and I start fresh.

That's done now. And the final part will be to get Seaweed up and running. The final configuration of the cooling system has not been determined. That's coming.

And in the meantime, wish me luck. Prayers are certainly welcome.

Also, as always, a huge thank you to the Trawler Forum family. I'd be stuck i Carrabelle if it weren't for you and I have to tell you, St. Pete is WONDERFUL. It's beautiful, and the waters are green.

Can't wait to enjoy more of the area.

J