Shoalwaters

Guru

- Joined

- Feb 24, 2008

- Messages

- 681

- Location

- St. Lucia, West Indies

- Vessel Name

- "Dragon Lady"

- Vessel Make

- DeFever 41

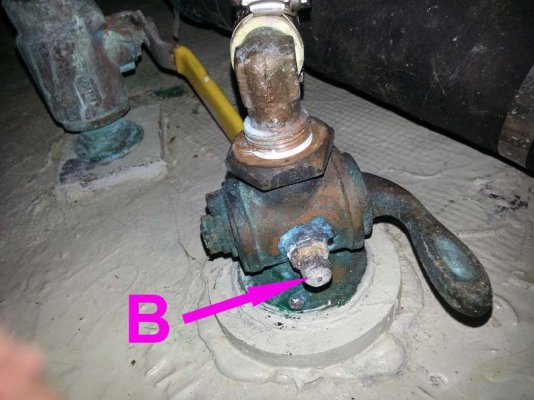

The pics below are of the small (1/2" - 3/4"?) seacock that supplies seawater to my aft head. I have not exercised it for the better part of a year and it now refuses to budge. I could apply mucho leverage to the handle but that way leads to tears.

The plug appears to be tapered. Can I slacken nut "A" about 1/4 turn and tap "axially" with a soft-faced mallet to loosen the plug in its barrel?

A search of the forum suggests that "B" might be a drain. I am not familliar with these - can I replace it with a grease nipple? If so, can I do the replacement with the boat in the water?

At next haul out I will remove and service the seacock properly, but for now I just want the head to work.

If anyone reckognises the make, I would be grateful for a scan of the service manual or whatever literature is available. This is original equipment in a 1984 DeFever.

Thanks in advance for the input.

The plug appears to be tapered. Can I slacken nut "A" about 1/4 turn and tap "axially" with a soft-faced mallet to loosen the plug in its barrel?

A search of the forum suggests that "B" might be a drain. I am not familliar with these - can I replace it with a grease nipple? If so, can I do the replacement with the boat in the water?

At next haul out I will remove and service the seacock properly, but for now I just want the head to work.

If anyone reckognises the make, I would be grateful for a scan of the service manual or whatever literature is available. This is original equipment in a 1984 DeFever.

Thanks in advance for the input.