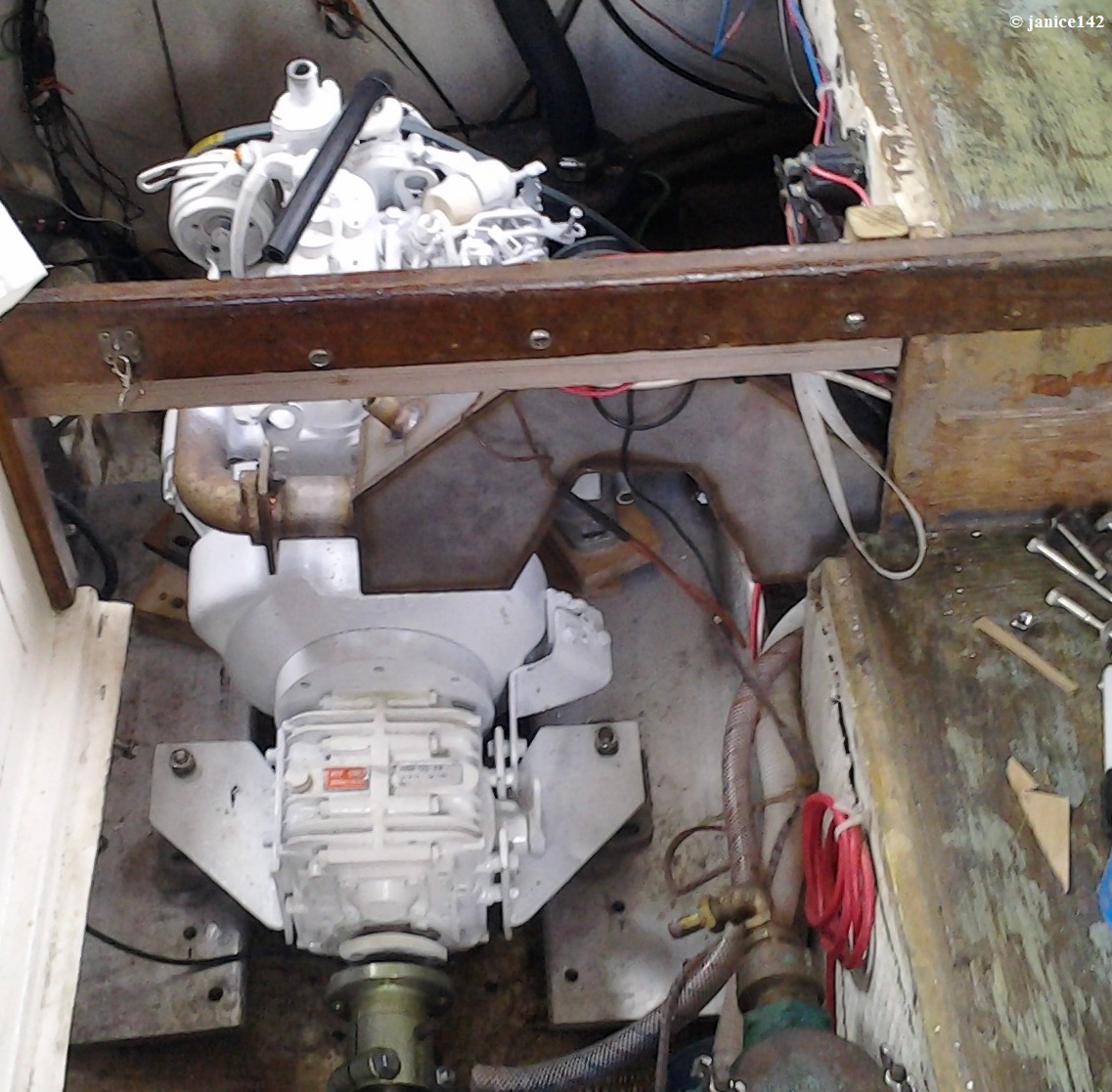

Okay. The pump that I'd titled Hyd is NOT hydraulic. The mechanic looked it up and said it was a Jabsco F5B8007 with 1" ports. Variable pulley driven. V-belt.

So I came down to the boat and checked. The numbers on the pump that are visible read 6523-8000

It's mounted. I did not realize as it too was painted white like the engine. I was going from my picture titles. So the raw water pump is okay. She was just less than $300 as I recall, so price is in line with what has been suggested a raw water pump costs.

Regarding the heat exchanger: It is from a Mercury V8 engine and is "much too big" but it was free. It's mounted on the forward bulkhead. A wooden cradle supports both ends.

Rubber will go between copper unit and wood so vibration should not cause pin holes.

Part of the confusion is accurately described (see David's comments above)as me not fully understanding how it will work. This engineering/engine stuff is not my strong suit. I've learned way more about motors than I wanted to know. And I'm still a neophyte.

It all seems so simple and reasonable in the shop and until I get back to the boat and read here... then confusion! I am better at comprehending, but I'm still no where near what an experienced motor guy would know intuitively.

At one time the boys had talked about rigging the heat exchanger to be a water heater and/or to heat the boat should I take her further north. I did not encourage (nor discourage) the comments.

Frankly, I want the swap completed first. If the possibility exists later to have hot water or a heating system using what's here all the better. But first things first: make the motor go.

And the mechanic as much as admitted that Steve would be on the boat when the A/C arrives. I can well appreciate that. In the pilothouse last week (albeit near the overhead) temperatures were in the triple digits. Working in the bilge wasn't much cooler.

Sitting in front of fans is one thing... an entirely different thing than working.

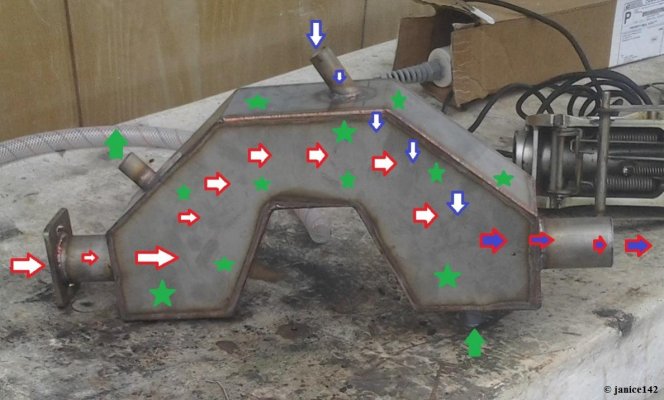

The stainless manifold will have two supports. One where it bolts on and then mid-way where a brace will bolt on to the motor -- four bolts. It's going to be attached here: ((near the lower right motor mount and directly to the right of the bell housing))

The mount is angled. It has not been cut from steel. The mock-up is here. Ditto metal.

At the shop today the boys were saying she'd run very soon. Just a "little bit" more to do. Specifically that's the hoses. And the bracket for the stainless.

And thank you for putting up with my less than lucid explanations. I'm way over my head and your questions do have value. They are helpful and I am thankful for the input.

There is no shop manual that I can find for the Kubota 720-40. I've looked. Once I find something that will suffice, I'll buy it or have it printed if it's a digital version. I need paper versus screen time when studying something like this.

As for the manifold already built versus a stainless elbow? Well, I'm keeping the elbow option open for certain. I do not fully understand the reasoning behind it (except it's to cool the exhaust pipe) ...

If you want one of those stainless elbows for a Yanmar, this website has them at the best price:

ExhaustElbow.com -- A friend has a Yanmar and I pointed him over there after reading about the company.

That, and the risers on Beast (the gasoline engine) were iron.... I went through three sets of risers on Beast.

J, still learning.