Bigfish

Senior Member

- Joined

- Jan 25, 2013

- Messages

- 297

- Location

- USA

- Vessel Name

- My Lady

- Vessel Make

- Formosa 42 Double Cabin

Hi folks,

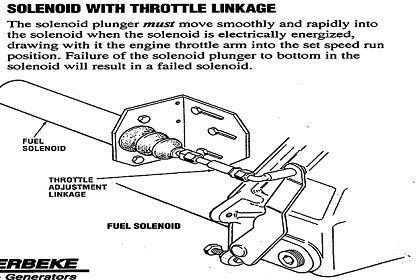

I have a Westerbeke diesel 7.7 KW genset and was told by a mechanic my fuel solenoid was bad. It wouldn't pull the throttle all the way back but it would lock in place with a little push. The battery was recharged and checked but he told me to get another solenoid which I did for $167 online.

While I waited 2 weeks for my first paycheck at West Marine to arrive and another week for the part, I was starting the generator which would barely idle, then I'd jump down and push in the solenoid. I was doing this twice a day just to keep the fridge cold and the batteries charged.

When the new solenoid arrived, I carefully replaced the old one and made sure all the wires were to the same terminals but it also wouldn't pull in over half way, identical to the "bad" one I'd replaced. I tried to start it twice and only briefly then called the mechanic who came over and checked all the wiring and the adjustment. He guessed the battery was low and told me to run the generator for a while and charge the battery then try it again. To start it he had to nudge it in all the way when I pressed the fuel pump switch. I ran it for 3 hours and enjoyed the air conditioning but was skeptical about this mechanic's expertise as he seemed pretty unsure of his diagnosis as the new one was acting the same as the old one.

After I shut it off I tried to start it again immediately and the solenoid acted the same as it had before and I was unable to start the generator. I wasn't surprised but it was late and I went to bed. Yesterday before I left for work I tried to start it as I had with the old one where it would start but just barely running at low idle until I was able to jump down and push in the solenoid but it wouldn't idle long enough for me to do that. I didn't have time to fool with it and went to work. When I got back from work I tried it again with no luck. I then realized I had a piece of molding that was just long enough to reach from the starting panel down to the arm of the throttle and I started the generator and pushed in the solenoid with the stick. I checked the voltage and it was adjusted a little low so I ran one air conditioner and the fridge and a few other things and the voltage was right at 120 volts on the meter on my panel. The gage on the Westerbeke panel wasn't showing any output at all and I tapped on the glass thinking it may be a stuck gauge but it didn't move. Everything else was normal so I decided to let it run to get the batteries back up as I have no solar panels. Also, my house batteries are very bad and need to be replaced but I don't have the money yet. 20 minutes later the generator shut off automatically and i jumped up to see what was wrong and that's when I smelled the fried solenoid.

Went to get on the computer and realized my computer had gotten dripped on through an open hatch in a brief squall while I was at work and it would start but I couldn't use the mouse! I messed with it for 3 hours before finally being able to get everything working correctly but the 3 beers I had in the process put me to sleep.

Today's my day off and I've got no generator, my new 8D starting battery I put in two months ago is "aiding," the ailing house batteries for now but I've lost all confidence in my new "mechanic," and desperate to know where to go from here. My boss at WM has a list of reputable mechanics but they're all scheduled out for at least a week.

I still don't understand what happenend and why so I'm hesitant to put the old one back in for fear of frying it too.

Any help or suggestions would be greatly appreciated. Oh, and by the way, while I was waiting on the solenoid I decided to replace my hoses off the exhaust elbows on my mains because they looked very bad. I just brought the new hose from work but haven't put them on the nearly rusted out old exhaust elbows so I'm dead in the water at the moment.

This all snowballed as I lost a substantial source of income last year and have been squeeking by on very litlle.

Thanks again!

I have a Westerbeke diesel 7.7 KW genset and was told by a mechanic my fuel solenoid was bad. It wouldn't pull the throttle all the way back but it would lock in place with a little push. The battery was recharged and checked but he told me to get another solenoid which I did for $167 online.

While I waited 2 weeks for my first paycheck at West Marine to arrive and another week for the part, I was starting the generator which would barely idle, then I'd jump down and push in the solenoid. I was doing this twice a day just to keep the fridge cold and the batteries charged.

When the new solenoid arrived, I carefully replaced the old one and made sure all the wires were to the same terminals but it also wouldn't pull in over half way, identical to the "bad" one I'd replaced. I tried to start it twice and only briefly then called the mechanic who came over and checked all the wiring and the adjustment. He guessed the battery was low and told me to run the generator for a while and charge the battery then try it again. To start it he had to nudge it in all the way when I pressed the fuel pump switch. I ran it for 3 hours and enjoyed the air conditioning but was skeptical about this mechanic's expertise as he seemed pretty unsure of his diagnosis as the new one was acting the same as the old one.

After I shut it off I tried to start it again immediately and the solenoid acted the same as it had before and I was unable to start the generator. I wasn't surprised but it was late and I went to bed. Yesterday before I left for work I tried to start it as I had with the old one where it would start but just barely running at low idle until I was able to jump down and push in the solenoid but it wouldn't idle long enough for me to do that. I didn't have time to fool with it and went to work. When I got back from work I tried it again with no luck. I then realized I had a piece of molding that was just long enough to reach from the starting panel down to the arm of the throttle and I started the generator and pushed in the solenoid with the stick. I checked the voltage and it was adjusted a little low so I ran one air conditioner and the fridge and a few other things and the voltage was right at 120 volts on the meter on my panel. The gage on the Westerbeke panel wasn't showing any output at all and I tapped on the glass thinking it may be a stuck gauge but it didn't move. Everything else was normal so I decided to let it run to get the batteries back up as I have no solar panels. Also, my house batteries are very bad and need to be replaced but I don't have the money yet. 20 minutes later the generator shut off automatically and i jumped up to see what was wrong and that's when I smelled the fried solenoid.

Went to get on the computer and realized my computer had gotten dripped on through an open hatch in a brief squall while I was at work and it would start but I couldn't use the mouse! I messed with it for 3 hours before finally being able to get everything working correctly but the 3 beers I had in the process put me to sleep.

Today's my day off and I've got no generator, my new 8D starting battery I put in two months ago is "aiding," the ailing house batteries for now but I've lost all confidence in my new "mechanic," and desperate to know where to go from here. My boss at WM has a list of reputable mechanics but they're all scheduled out for at least a week.

I still don't understand what happenend and why so I'm hesitant to put the old one back in for fear of frying it too.

Any help or suggestions would be greatly appreciated. Oh, and by the way, while I was waiting on the solenoid I decided to replace my hoses off the exhaust elbows on my mains because they looked very bad. I just brought the new hose from work but haven't put them on the nearly rusted out old exhaust elbows so I'm dead in the water at the moment.

This all snowballed as I lost a substantial source of income last year and have been squeeking by on very litlle.

Thanks again!