You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boat Maneuvering with Separate throttle and Shift

- Thread starter pukeanddie

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

READY2GO

Guru

- Joined

- Jan 3, 2012

- Messages

- 521

- Location

- USA

- Vessel Name

- Walkabout

- Vessel Make

- 1989 Sea Ray 380 Aft Cabin

pukeanddie, in your original post you said you have had the boat 8 years. If you have not addapted to the dual lever by now you probably never will. Talk to hopcar and get a single lever control. We bought one from him that looks to be excellent quality but unfortunately I have not installed it yet to give you a good reveiw. We have dual stations so it was about $900 if I remember correctly.

One thing I have learned about the boat is that if something makes you uncomfortable or if it will give you more confidence in the boat or your ability to handle the boat is to CHANGE it. Don't just live with it.

One thing I have learned about the boat is that if something makes you uncomfortable or if it will give you more confidence in the boat or your ability to handle the boat is to CHANGE it. Don't just live with it.

psneeld

Guru

How many COULD adapt to a control system that shut the engine down when throttleling back?

I run a boat that many say is a 26 foot extension of my right hand, I shift and throttle with one hand on a dual control...and I seriously doubt adapting to a shutoff on the throttle would be easy.

I run a boat that many say is a 26 foot extension of my right hand, I shift and throttle with one hand on a dual control...and I seriously doubt adapting to a shutoff on the throttle would be easy.

READY2GO

Guru

- Joined

- Jan 3, 2012

- Messages

- 521

- Location

- USA

- Vessel Name

- Walkabout

- Vessel Make

- 1989 Sea Ray 380 Aft Cabin

How many COULD adapt to a control system that shut the engine down when throttleling back?

I run a boat that many say is a 26 foot extension of my right hand, I shift and throttle with one hand on a dual control...and I seriously doubt adapting to a shutoff on the throttle would be easy.

I agree with that. Wether he changes to a single lever or not the engine shut down needs to be changed regardless. It is dangerous.

Ski in NC

Technical Guru

CAV pump has a stop lever right next to throttle. Rig up a pull cable or string or whatever to use that for shutdown. Some have an electric solenoid on bottom of pump that can either be power to run or power to stop.

Right on top of pump next to shutdown lever is the throttle lever, adjust the stop screw on that to get normal idle speed, for a 236 it will be around 700-800rpm.

It would not be easy to put single lever on this boat, as I understand it is two stations. It takes something like a Panish box or electronics to get two station single lever to work.

Right on top of pump next to shutdown lever is the throttle lever, adjust the stop screw on that to get normal idle speed, for a 236 it will be around 700-800rpm.

It would not be easy to put single lever on this boat, as I understand it is two stations. It takes something like a Panish box or electronics to get two station single lever to work.

READY2GO

Guru

- Joined

- Jan 3, 2012

- Messages

- 521

- Location

- USA

- Vessel Name

- Walkabout

- Vessel Make

- 1989 Sea Ray 380 Aft Cabin

CAV pump has a stop lever right next to throttle. Rig up a pull cable or string or whatever to use that for shutdown. Some have an electric solenoid on bottom of pump that can either be power to run or power to stop.

Right on top of pump next to shutdown lever is the throttle lever, adjust the stop screw on that to get normal idle speed, for a 236 it will be around 700-800rpm.

It would not be easy to put single lever on this boat, as I understand it is two stations. It takes something like a Panish box or electronics to get two station single lever to work.

With Moorse true, but not with Kobelt controls. Hopcar can fix him right up.

- Joined

- Apr 15, 2008

- Messages

- 13,731

- Location

- California Delta

- Vessel Name

- FlyWright

- Vessel Make

- 1977 Marshall Californian 34 LRC

(I fixed the image link.)

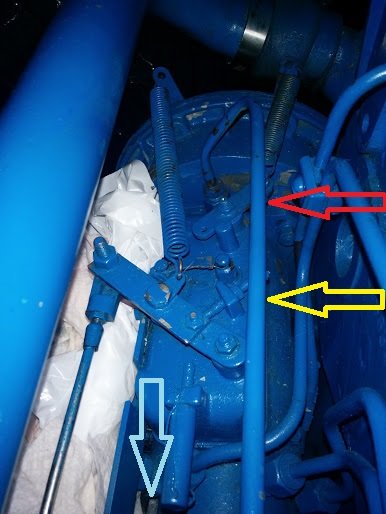

That bellcrank to the right of the long spring is the fuel cut off valve. That spring is holding it in the run position. There's normally a solenoid connected to the other end which pulls that bellcrank to the shutoff position to stop the engine. Sounds like your idle is set too low and you need to replace the solenoid. Not a tough job since you have the other parts in position.

Try it out....start your engine, let it run at idle and go to the ER and reposition the bellcrank. The engine should stop.

That bellcrank to the right of the long spring is the fuel cut off valve. That spring is holding it in the run position. There's normally a solenoid connected to the other end which pulls that bellcrank to the shutoff position to stop the engine. Sounds like your idle is set too low and you need to replace the solenoid. Not a tough job since you have the other parts in position.

Try it out....start your engine, let it run at idle and go to the ER and reposition the bellcrank. The engine should stop.

Last edited:

pukeanddie

Veteran Member

- Joined

- Mar 25, 2015

- Messages

- 26

- Location

- United States

- Vessel Name

- Mooncusser

- Vessel Make

- Rosborough RF28

Ok, that shutoff lever seems simple enough, but my problem is going to be making that work at both helm stations. I'm guessing that is why this setup exists in the first place.

I think my plan will be to drill a small hole in both my morse controls and keep a peg on a small chain that I can use to limit throttle arm movement, but easily remove to shut off the engine.

I think my plan will be to drill a small hole in both my morse controls and keep a peg on a small chain that I can use to limit throttle arm movement, but easily remove to shut off the engine.

- Joined

- Apr 15, 2008

- Messages

- 13,731

- Location

- California Delta

- Vessel Name

- FlyWright

- Vessel Make

- 1977 Marshall Californian 34 LRC

I was on a trip when my solenoid failed. I disconnected it and ran a parachute cord to the bellcrank to activate the fuel shutoff valve. The other end of that cord was run to my fwd ER door where I could access it from the lower helm. When it was time to shut down, I'd just lean over and pull the cord.

You really only need the shutdown at the lower helm. My FB shutdown controls haven't worked since I bought the boat 8 years ago. No big deal to me since I always start and stop from the lower helm.

You really only need the shutdown at the lower helm. My FB shutdown controls haven't worked since I bought the boat 8 years ago. No big deal to me since I always start and stop from the lower helm.

Northern Spy

Guru

- Joined

- Feb 5, 2012

- Messages

- 4,075

- Location

- Canada

- Vessel Name

- Northern Spy

- Vessel Make

- Nordic Tug 26

- Joined

- Oct 1, 2007

- Messages

- 7,331

- Location

- Texas

- Vessel Name

- Floatsome & Jetsome

- Vessel Make

- Meridian 411

Can you rig it up so your shutdown is not the throttle lever? That would make it simpler.

Personally, this would be the ONLY solution for me. I cannot imagine it would be too difficult to engineer.

Capt.Bill11

Guru

Ok, that shutoff lever seems simple enough, but my problem is going to be making that work at both helm stations. I'm guessing that is why this setup exists in the first place.

I think my plan will be to drill a small hole in both my morse controls and keep a peg on a small chain that I can use to limit throttle arm movement, but easily remove to shut off the engine.

Based on the photo all you have to do is adjust the throttle stop to keep the idle from dropping to low.

- Joined

- Apr 15, 2008

- Messages

- 13,731

- Location

- California Delta

- Vessel Name

- FlyWright

- Vessel Make

- 1977 Marshall Californian 34 LRC

Check out the knob control push/pull cables on this page. You could rig a stop cable for $30.

McMaster-Carr

McMaster-Carr

pukeanddie

Veteran Member

- Joined

- Mar 25, 2015

- Messages

- 26

- Location

- United States

- Vessel Name

- Mooncusser

- Vessel Make

- Rosborough RF28

Thanks for all the good advice.

I am hesitant to install only a single stop cable since I have a flybridge helm as well. I would want to be able to quickly turn off the engine in an emergency such as oil pressure drop, right?

I am hesitant to install only a single stop cable since I have a flybridge helm as well. I would want to be able to quickly turn off the engine in an emergency such as oil pressure drop, right?

Bay Pelican

Moderator Emeritus

To give you an added incentive, you may have both liability and insurance problems with the current setup if God forbid anything should happen. Unless you can establish that this was original and met the standards of the time I would think you might have problems claiming insurance coverage in an accident.

Nomad Willy

Guru

Frequently I stand a bit sideways facing to stbd. I reach accross w my right arm and do the shifting .. I think my shift and throttle are not on the usual sides. I usually make stbd landings. Then w my thumb and forefinger I run the throttle. This way I'm not switching hands and I can see well aft but fwd too. I have a throttle stop at 600rpm cold and 900 warm. When I'm backing I don't use the rudder unless I need to swing the stern w fwd gear. When needed or wanted I use up to 3/4 throttle in both gears .. more so in reverse.

Lots of time for making observations if there's no wind or current so 1000rpm is fine. But often quick maneurvers are necessary to move the boat (or one end of it) out of danger or worse. My $0.02

Lots of time for making observations if there's no wind or current so 1000rpm is fine. But often quick maneurvers are necessary to move the boat (or one end of it) out of danger or worse. My $0.02

Island Cessna

Senior Member

- Joined

- Feb 19, 2011

- Messages

- 307

I think the root of the problem is simply that at some time the stop cable broke and someone jury-rigged it by setting the low idle to zero, then never fixed the stop cable. Replace the stop cable with one or two cables and readjust the idle stop and you are back to a correct and functional setup.

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

... I usually make stbd landings. Then w my thumb and forefinger I run the throttle. ..

I also usually make starboard landings. I'm able to reach the wheel as well as engine and thruster controls with the left hand when standing on the starboard deck for best visibility. Since the boat has starboard propwalk, applying power helps snuggle the boat to the dock when landing. When leaving, the bow thruster can angle the stern to port to counter the propwalk.

C lectric

Guru

Don't mickey mouse a mickey mouse.

Readjust the low speed stop properly so the engine no longer stalls. That is not correct and as pointed out may be dangerous/disastrous.

Then properly repair the shutdown with either an electric solenoid as the engine was designed to have or rig a manual cable, two which could be tandemed or paralleled, to do the shutdown properly and safely.

Tandem meaning one cable from bridge connects to the lower helm cable so only one cable goes to the shutdown lever on the pump from the join at the lower helm.

Parallel meaning two cables go directly to the the shutdown lever on the pump.

Readjust the low speed stop properly so the engine no longer stalls. That is not correct and as pointed out may be dangerous/disastrous.

Then properly repair the shutdown with either an electric solenoid as the engine was designed to have or rig a manual cable, two which could be tandemed or paralleled, to do the shutdown properly and safely.

Tandem meaning one cable from bridge connects to the lower helm cable so only one cable goes to the shutdown lever on the pump from the join at the lower helm.

Parallel meaning two cables go directly to the the shutdown lever on the pump.

Conrad

Guru

- Joined

- Oct 19, 2007

- Messages

- 1,972

- Location

- Canada

- Vessel Name

- Blue Sky

- Vessel Make

- Nordic Tugs 42 Hull #001

Years ago our purchased new sailboat came with a Morse dual lever system that was designed such that pulling all the way back on the throttle would shut down the engine. So they did manufacture them that way, although I don't think it was the brightest design feature.

Tom.B

Moderator Emeritus

- Joined

- Jul 30, 2009

- Messages

- 5,839

- Location

- USA

- Vessel Name

- Skinny Dippin'

- Vessel Make

- Navigator 4200 Classic

Hey... you guys check my work, but I think this is all you need to do. All of these parts can be just off-the-shelf auto store or West Marine parts. You might have to source a used solenoid or get one from a local commercial truck parts store.

Attachments

Last edited:

jleonard

Guru

- Joined

- Jun 25, 2008

- Messages

- 5,061

You really do not NEED to be able to shut down from your upper station.

So a cable or switch from below will be fine.

So a cable or switch from below will be fine.

Capt.Bill11

Guru

You really do not NEED to be able to shut down from your upper station.

So a cable or switch from below will be fine.

Until it sticks in gear and you're heading straight for some one else's boat.

what_barnacles

Guru

Red Arrow is shut off

Yellow Arrow is idle stop screw

On the side by the Light Blue Arrow is where you would find a solenoid if there is one.

I dont see any mechanical connection between the throttle and the shutoff levers.

Northern Spy

Guru

- Joined

- Feb 5, 2012

- Messages

- 4,075

- Location

- Canada

- Vessel Name

- Northern Spy

- Vessel Make

- Nordic Tug 26

I dont see any mechanical connection between the throttle and the shutoff levers.

Exactly. That is the problem. The fuel control is allowed to go below low idle until the engine starves and "stalls".

The OP should consider a simple pull cable to manually shut off the engine. This would allow him to use the control to adjust engine RPM. Most controls are set up so that full back on the fuel takes you to low idle. His shuts down the engine.

cappy208

Guru

Single lever controls use the same cables as the double.

I would heartily agree with the elimination of the ability to use low throttle as shutdown issue. That is simply out of adjustment.

Have you looked at the governor for the shutdown lever? I would bet dollars to donuts that there IS a lever there ( all diesels have some type of compression release or fuel rack lever) and it probably has (had) a separate shutdown pull, push, or electric solenoid to shut it down.

Thinking back to the 40 to 50 diesel boats I have run over the course of my career I do not recall one that has ever had the primary or even possible way to shut down the engine via the throttle lever. The most common way without using an electric solenoid is to use a semi rigid push/pull cable to shut it down and then push it back in so it will run next time. Not every station needs the shutdown ability. Just the main one, which is in fairly close proximity to the start button. If you go with cable, you need to look for 'panel mount cable'. With a 'T' handle.

I would heartily agree with the elimination of the ability to use low throttle as shutdown issue. That is simply out of adjustment.

Have you looked at the governor for the shutdown lever? I would bet dollars to donuts that there IS a lever there ( all diesels have some type of compression release or fuel rack lever) and it probably has (had) a separate shutdown pull, push, or electric solenoid to shut it down.

Thinking back to the 40 to 50 diesel boats I have run over the course of my career I do not recall one that has ever had the primary or even possible way to shut down the engine via the throttle lever. The most common way without using an electric solenoid is to use a semi rigid push/pull cable to shut it down and then push it back in so it will run next time. Not every station needs the shutdown ability. Just the main one, which is in fairly close proximity to the start button. If you go with cable, you need to look for 'panel mount cable'. With a 'T' handle.

LarryM

Guru

- Joined

- Aug 5, 2011

- Messages

- 1,069

- Location

- USA

- Vessel Name

- Pelago

- Vessel Make

- Wellcraft 3300 Coastal

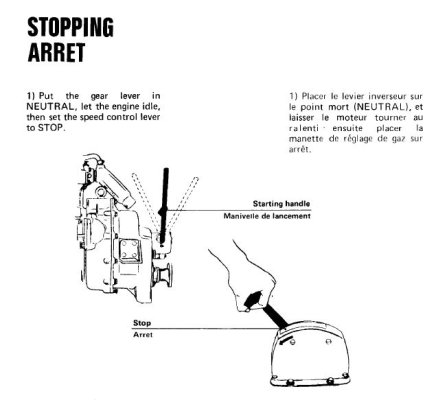

Believe it or not, the Yanmar 2QM20 actually featured a "Stop" position on the throttle quadrant. It required pulling the throttle lever back beyond the "Idle" detent position into the "Stop" position to stop the engine. This was not a single lever combination control, there was a separate gear selector control. It was very problematic and was discontinued on their later auxiliary diesels. The injection pump had no stop lever or stop solenoid. The only way to stop the engine was using the "Stop" position on the throttle. Here is the detail from the owners manual. It was a mess and hard to keep adjusted.

In looking at the pic of the injection pump provided by the OP, there definitely appears to be a stop lever visible. Not like this weird Yanmar stop arrangement.

In looking at the pic of the injection pump provided by the OP, there definitely appears to be a stop lever visible. Not like this weird Yanmar stop arrangement.

Attachments

Last edited:

BruceK

Moderator Emeritus

- Joined

- Oct 31, 2011

- Messages

- 13,347

- Vessel Name

- Sojourn

- Vessel Make

- Integrity 386

Fine for the lawnmower, not fine for the boat.Exactly. That is the problem. The fuel control is allowed to go below low idle until the engine starves and "stalls".

Similar threads

- Replies

- 42

- Views

- 3K