I've got one off a D950 sitting in the shop. Not sure if it will fit on a D720.

That won't fit... the 720-40 is different from the 850 and 950 which are quite prevalent.

As for the exhaust, well, we are going with what is built. Another individual suggested coating the inside of the pipe where the raw water enters (just before the hose attaches with a heat-resistant silicone. I don't know about that but there is nothing between the hose and the exit of the boat except a Vernier water-lift muffler.

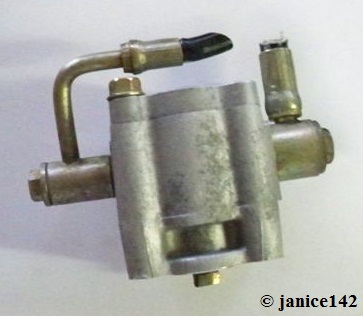

That pump from my title seems to indicate hydraulic. Title is: KubotaHydPump-GP036-2-2

As I understand it, that will be pushing a combination of fresh water and coolant through the system. Is there a reason that use would be contraindicated? Is it "no" for salt but not fresh? And I could be wrong. It *might* be for the raw water injection but I don't think so.

I'll ask about that tomorrow too.

Tomorrow is the day. Mechanic is to be here in the morning. And there are no parts that are due in so none of that boatyard fertilizer where they say "Yes, your parts were ordered a couple weeks ago, but one was back-ordered so I had them hold to ship all together. Let me check on that today" followed by placement of the order.

As for the design that is off from the standard? Well, I don't know for certain if it will work. It's bought and paid for so will give it a shot. If the cooling system won't work my IR gun should tell me so.

And coating the inside of the pipe (from nipple to exit) is an option brought up elsewhere. Another suggestion to anneal perhaps came in... I am concerned about corrosion.

Wonder if corroseal would help/work? The shrimp boat just bought 5 gallons so there's some of that magic stuff right here.

David said: "1. She is using original non jacketed manifold. OK probably but keep anything combustible a foot or more away and provide more extensive engine cooling- vents and maybe an exhaust fan."

I've been assured the box will be cool enough to touch. That said, there are vents in the bilge (starboard intake of air, port is exit) and two 4" blowers. The bilge is open and airy -- 30" fore and aft and about 7' wide. Oh and 3' deep at centerline.

And Ski said: "Boat has a water lift muffler, so there really needs to be no high rise dry pipe either, provided the outlet of the muffler has enough rise."

Yes, the Vernier hose goes up and then down to the exhaust out the side of the boat. The high point is well above the waterline.

Xsbank said: "Just get a wet manifold off an Onan genset. There must be tons of them around."

Too true. I'm willing to give this a trial and if it doesn't work go with the standard wet exhaust. The thing is, the investment is there. If we don't try we doom it to failure. If this does work, good. Make that Great.

But if not, switching is not going to be a problem either. We test first before throwing out what's here. I hope it functions but am not married to it either. I am no worse off for having tested it.

[The initial engine swap I paid for. This one, all the labor is free. So trialing the stainless won't harm me in the least. Except timewise.]

I am concerned about the corrosion issue a the point of raw water input. Would Corroseal protect the metal or is that just for steel, not stainless? Ditto, what did you think of the idea floated re heat-resistant silicone over the pipe from where the raw water enters to the exit where the hose attaches?

And I do appreciate the input. This is new territory. And yes, I do wish I'd posted about the plan earlier. I'm always smarter after the fact, however I am willing to test things first. And if they don't work, I move on.

Always have a Plan B, even if it has to be created on the fly... And after B, there are 24 more letters in the alphabet.