Shoalwaters

Guru

- Joined

- Feb 24, 2008

- Messages

- 681

- Location

- St. Lucia, West Indies

- Vessel Name

- "Dragon Lady"

- Vessel Make

- DeFever 41

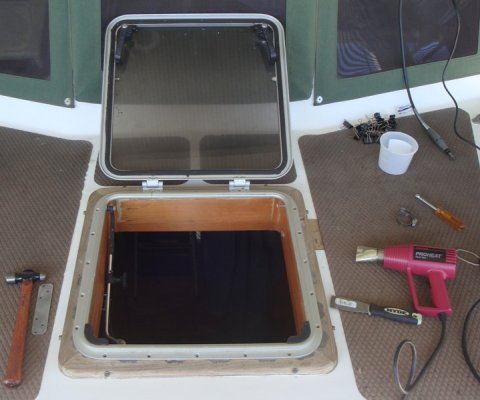

The bronze port-lights on my boat look horrible and this one leaks. I want to remove each in turn, reglaze, polish and refit.

How do I get them off? I see phillips heads inside and out - does one screw into the other?

What should i use to restore the bronze finish?

How do I re-glaze them?

What sealant should I use for re-bedding them?

How do I get them off? I see phillips heads inside and out - does one screw into the other?

What should i use to restore the bronze finish?

How do I re-glaze them?

What sealant should I use for re-bedding them?