You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Diesel polish system

- Thread starter lanoronha

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Hello

I live in Brazil and my boat is a 39 fiberglass trawler with twin MWM 4 cil engines with 85 HP each. I have 2 Inox tanks with 800 liters each. The diesel quality here is not so good,

and I want a system capable to keep the fuel as clean, pure and water free as possible.

I live in Brazil and my boat is a 39 fiberglass trawler with twin MWM 4 cil engines with 85 HP each. I have 2 Inox tanks with 800 liters each. The diesel quality here is not so good,

and I want a system capable to keep the fuel as clean, pure and water free as possible.

MikeM

Senior Member

Yes.

Where are you located?

What do you need the system to do?

What kind of boat? Motor?

How many fuel tanks?

Richard,

Did you build a system for Dauntless? If so, I would love to get the plans.

Mike

Mike Metts

KK 42-165

Virginia Beach, VA

Sent from my iPad using Trawler Forum

caltexflanc

Guru

Here's a really good one that you can build yourself.

Captn Wil's Fuel Polishing System: Trawlers & Trawlering How To

For most purposes, going to a multi progressive filtering system will do the job unless the fuel is really awful, as in very old, bottom of the barrel stuff. Sticking one of the big Fleetguard filters in front of a traditional two step filter set up (primary and engine mounted).Good idea to have this in place anyway, polishing system or no, if you do not have consistent access to clean fuel.

SMX Multi-Stage Fuel Fueltration™ System Kits

Captn Wil's Fuel Polishing System: Trawlers & Trawlering How To

For most purposes, going to a multi progressive filtering system will do the job unless the fuel is really awful, as in very old, bottom of the barrel stuff. Sticking one of the big Fleetguard filters in front of a traditional two step filter set up (primary and engine mounted).Good idea to have this in place anyway, polishing system or no, if you do not have consistent access to clean fuel.

SMX Multi-Stage Fuel Fueltration™ System Kits

Capt.Bill11

Guru

Hello

Please do someone knows how to build an custom diesel polishing system at a razonable cost?

What do you consider as razonable ?

The cheapest system in the long run is to increase the size of your fuel filters and buy some extra filter elements and take the boat out into some rough seas for several hours.

Wxx3

Dauntless Award

- Joined

- Jan 10, 2013

- Messages

- 2,820

- Location

- USA

- Vessel Name

- Dauntless

- Vessel Make

- Kadey Krogen 42 - 148

OK.

I'll see if I can find a picture.

I like my system a lot. It has served me well and would have served even better had I run it more often after leaving horta. The only problem was the nut behind the wheel.

It's 12v and features a Racor 900 and a manifold that allows me to transfer fuel between the tanks. The only limitation is is that I can only polish the fuel in the tank that the engine is using. this has turned out not to be a issue.

I'll look for the manifold cost. Installation was a day or less.

I'll see if I can find a picture.

I like my system a lot. It has served me well and would have served even better had I run it more often after leaving horta. The only problem was the nut behind the wheel.

It's 12v and features a Racor 900 and a manifold that allows me to transfer fuel between the tanks. The only limitation is is that I can only polish the fuel in the tank that the engine is using. this has turned out not to be a issue.

I'll look for the manifold cost. Installation was a day or less.

MikeM

Senior Member

OK.

I'll see if I can find a picture.

I like my system a lot. It has served me well and would have served even better had I run it more often after leaving horta. The only problem was the nut behind the wheel.

It's 12v and features a Racor 900 and a manifold that allows me to transfer fuel between the tanks. The only limitation is is that I can only polish the fuel in the tank that the engine is using. this has turned out not to be a issue.

I'll look for the manifold cost. Installation was a day or less.

Great! Thanks.

I am able to transfer fuel between tanks now, although the fuel transfer pump is very slow and loud. I can't imagine using it to polish the fuel.

Mike Metts

KK 42-165

Virginia Beach, VA

Sent from my iPad using Trawler Forum

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

Polishing may clean the fuel IN the tank, but the gunk stuck on the side walls will not be cleaned.

This usually takes scrubbing thru a hand hole.

When thr motion of the ocean becomes enough to move some of the crud , your are back to clumps in the fuel.

A day tank might help , as would a set or two of filters with a dash momitor of the suction across the filterr banl.

Murphy sells the gauge.

This usually takes scrubbing thru a hand hole.

When thr motion of the ocean becomes enough to move some of the crud , your are back to clumps in the fuel.

A day tank might help , as would a set or two of filters with a dash momitor of the suction across the filterr banl.

Murphy sells the gauge.

Heron

Guru

- Joined

- Nov 5, 2014

- Messages

- 1,304

- Location

- USA

- Vessel Name

- Heron (2)

- Vessel Make

- '88 Cape Dory 28 Flybridge #115

Great! Thanks.

I am able to transfer fuel between tanks now, although the fuel transfer pump is very slow and loud. I can't imagine using it to polish the fuel.

I just measured the transfer rate on mine the other day using a Walbo pump. 30 GPH, just as rated. With (2) 60 gallon tanks this is fine for my small boat.

When in "Polishing/transfer" mode (one valve on the right to either polish/transfer or run) it pulls through a large 27 micron Fleetgaurd filter and a 10 micron Sierra. When in Run, it also pushes through a Racor and on engine primary filter. Transfer direction and tank selection done with my existing valves. Very simple. Just added a pump and 3 way valve to make it all work. <$200

Last edited:

Alaskan Sea-Duction

Guru

- Joined

- Jul 6, 2012

- Messages

- 8,057

- Location

- USA

- Vessel Name

- Alaskan Sea-Duction

- Vessel Make

- 1988 M/Y Camargue YachtFisher

Don't forget to teat your fuel too after you polish it.....

Heron

Guru

- Joined

- Nov 5, 2014

- Messages

- 1,304

- Location

- USA

- Vessel Name

- Heron (2)

- Vessel Make

- '88 Cape Dory 28 Flybridge #115

Don't forget to teat your fuel too after you polish it.....

Don't worry.....This all started after this discovery...:

(No bugs, but plenty of Asphaltines..)

http://www.trawlerforum.com/forums/s32/funky-fuel-filters-19536.html

- Joined

- Mar 17, 2012

- Messages

- 4,279

- Location

- Australia

- Vessel Name

- Insequent

- Vessel Make

- Ocean Alexander 50 Mk I

unless you already have many of the components or can source them cheaply you will likely find a ready-made unit more cost-effective than building one.

With my Reverso the manifolds allow draw from any tank and return to any tank. It can also purge air from engine filters and supply lines.

With my Reverso the manifolds allow draw from any tank and return to any tank. It can also purge air from engine filters and supply lines.

Attachments

caltexflanc

Guru

Don't forget to teat your fuel too after you polish it.....

I'm all for "teats" but why use an expensive additive unless you are letting the boat sit for a long time after polishing? And if so, why polish in the first place?

Alaskan Sea-Duction

Guru

- Joined

- Jul 6, 2012

- Messages

- 8,057

- Location

- USA

- Vessel Name

- Alaskan Sea-Duction

- Vessel Make

- 1988 M/Y Camargue YachtFisher

I'm all for "teats" but why use an expensive additive unless you are letting the boat sit for a long time after polishing? And if so, why polish in the first place?

Well if you are investing in your cleanout as I did, then treating the fuel on fill up or every 6 months is good preventative maintenance. A $30 bottle can help you save big $$$

RT Firefly

Enigma

Greetings,

Mr. ASD. "...Teat..." ?? Thanks Mr. cal. I missed that one. I'll admit, I have NO idea where THIS thread is going...Apologies to Mr. lan...

Mr. ASD. "...Teat..." ?? Thanks Mr. cal. I missed that one. I'll admit, I have NO idea where THIS thread is going...Apologies to Mr. lan...

caltexflanc

Guru

Well if you are investing in your cleanout as I did, then treating the fuel on fill up or every 6 months is good preventative maintenance. A $30 bottle can help you save big $$$

Why? is the boat in storage?

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

Storage is not a hassle , water in the fuel allows the bugs to have a place to live.

Get rid of the water , and the tank will stay clean , almost forever.

Poison goop may kill the bugs for a while , but does not solve water the problem.

Old fuel clumping is no problem as most filters can easily handle big clumps.

Get rid of the water , and the tank will stay clean , almost forever.

Poison goop may kill the bugs for a while , but does not solve water the problem.

Old fuel clumping is no problem as most filters can easily handle big clumps.

Alaskan Sea-Duction

Guru

- Joined

- Jul 6, 2012

- Messages

- 8,057

- Location

- USA

- Vessel Name

- Alaskan Sea-Duction

- Vessel Make

- 1988 M/Y Camargue YachtFisher

Greetings,

Mr. ASD. "...Teat..." ?? Thanks Mr. cal. I missed that one. I'll admit, I have NO idea where THIS thread is going...Apologies to Mr. lan...

Teats? Did I say teats, but that is a mighty fine set...

Alaskan Sea-Duction

Guru

- Joined

- Jul 6, 2012

- Messages

- 8,057

- Location

- USA

- Vessel Name

- Alaskan Sea-Duction

- Vessel Make

- 1988 M/Y Camargue YachtFisher

Why? is the boat in storage?

Regardless if it is in storage or not you should treat your fuel, unless you burn it faster than you fill up. Water is the big creator of fuel tank bugs. Next time you open your fill cap, see if it has water droplets on the underside of the cap....

"It is cheaper to do preventive maintenance (i.e. Servicing) than it is to have repairs!"

Tom.B

Moderator Emeritus

- Joined

- Jul 30, 2009

- Messages

- 5,839

- Location

- USA

- Vessel Name

- Skinny Dippin'

- Vessel Make

- Navigator 4200 Classic

Regardless if it is in storage or not you should treat your fuel, unless you burn it faster than you fill up. Water is the big creator of fuel tank bugs. Next time you open your fill cap, see if it has water droplets on the underside of the cap....

"It is cheaper to do preventive maintenance (i.e. Servicing) than it is to have repairs!"

There has been a lot of discussion about this. We have had a few experts (read: industry professionals) chime in on this topic. IIRC, the conscientious was to be VERY careful using additives. You can do more harm than good. You don't know what the oil company has added and you have a better-than-not chance of making things worse. The advice was to just use your fuel. Don't let it sit regardless of what you pour into it. 90-180 day max.

Anyway, regarding the OP's question... Here is what I came up with. Utilizing the amazing talents of the TF group. The AC motor/pump was the way to go. Quiet and fast polishing or transferring fuel.

Read: http://www.trawlerforum.com/forums/s6/fuel-system-upgrade-project-episode-ii-3761.html

At the end of the day, it wasn't terribly expensive to make, but it DID take some time to design, build, and install. Worth it for sure.

Alaskan Sea-Duction

Guru

- Joined

- Jul 6, 2012

- Messages

- 8,057

- Location

- USA

- Vessel Name

- Alaskan Sea-Duction

- Vessel Make

- 1988 M/Y Camargue YachtFisher

Thanks Tom,

The advice I received (thus shared here) came from a professional who has been polishing fuel for over 40 years. His advice has yet to fail.....

The advice I received (thus shared here) came from a professional who has been polishing fuel for over 40 years. His advice has yet to fail.....

looks good

Sincerely

Marty

Hello could you send of post more pictures of your set up, I have purchased a 3 way valve and a pump. thanks for posting the picture.I just measured the transfer rate on mine the other day using a Walbo pump. 30 GPH, just as rated. With (2) 60 gallon tanks this is fine for my small boat.

When in "Polishing/transfer" mode (one valve on the right to either polish/transfer or run) it pulls through a large 27 micron Fleetgaurd filter and a 10 micron Sierra. When in Run, it also pushes through a Racor and on engine primary filter. Transfer direction and tank selection done with my existing valves. Very simple. Just added a pump and 3 way valve to make it all work. <$200

Sincerely

Marty

Heron

Guru

- Joined

- Nov 5, 2014

- Messages

- 1,304

- Location

- USA

- Vessel Name

- Heron (2)

- Vessel Make

- '88 Cape Dory 28 Flybridge #115

Hello could you send of post more pictures of your set up, I have purchased a 3 way valve and a pump. thanks for posting the picture.

Sincerely

Marty

I'll be down at the boat tomorrow and shoot a few More detail shots.

BTW both my kids live in Colorado Springs! You're a good piece from the water..

Heron

Guru

- Joined

- Nov 5, 2014

- Messages

- 1,304

- Location

- USA

- Vessel Name

- Heron (2)

- Vessel Make

- '88 Cape Dory 28 Flybridge #115

Hello could you send of post more pictures of your set up, I have purchased a 3 way valve and a pump. thanks for posting the picture.

Sincerely

Marty

Found one other.....Valve up for run and fuel to the Racor, Valve down for polishing and transfer (T'd into the return). Pump does not need to be on in the run position.

I'll still do some more tomorrow.

Wxx3

Dauntless Award

- Joined

- Jan 10, 2013

- Messages

- 2,820

- Location

- USA

- Vessel Name

- Dauntless

- Vessel Make

- Kadey Krogen 42 - 148

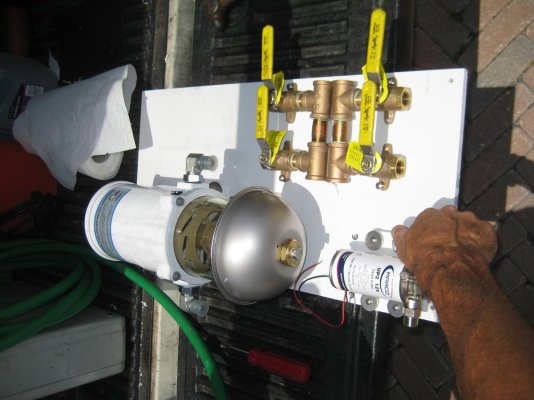

Dauntless' Fuel Polishing System

THe Racor 900 costs about $250 and pumps almost exactly 90 gal/hr.

The rest of the plumbing was less than $100.

It removed all of that asphalt stuff by the time I got to NY.

The filters, 2040 2 mic, cost $11 each. I buy them by the case from Amazon.

AFTER that polishing, I opened the inspection port, thanks to Larry on Hobo, expecting the worst, with mop in hand.

THe tank was as clean as a babies bottom that has been washing in diesel for a month.

My mop is still unused stored behind the gen. Bucket Head took care of the water.

I was also told my American Diesel, not to connect the polisher system to the feed lines of the engine, as the pressure would screw up the lift pump in prompt fashion. And it isn't. The fuel goes to either tank return.

email me at DauntlessNY if you have questions.

THe Racor 900 costs about $250 and pumps almost exactly 90 gal/hr.

The rest of the plumbing was less than $100.

It removed all of that asphalt stuff by the time I got to NY.

The filters, 2040 2 mic, cost $11 each. I buy them by the case from Amazon.

AFTER that polishing, I opened the inspection port, thanks to Larry on Hobo, expecting the worst, with mop in hand.

THe tank was as clean as a babies bottom that has been washing in diesel for a month.

My mop is still unused stored behind the gen. Bucket Head took care of the water.

I was also told my American Diesel, not to connect the polisher system to the feed lines of the engine, as the pressure would screw up the lift pump in prompt fashion. And it isn't. The fuel goes to either tank return.

email me at DauntlessNY if you have questions.

Attachments

stubones99

Guru

Tell me that left is UP, on the posted photo?

Otherwise the separator on the filter won't work!!!

The manual says :

Note -- mount the filter assembly as close to vertical (V) as possible. Do not

exceed 10o from vertical or the assembly may not function properly.

Otherwise the separator on the filter won't work!!!

The manual says :

Note -- mount the filter assembly as close to vertical (V) as possible. Do not

exceed 10o from vertical or the assembly may not function properly.

Northern Spy

Guru

- Joined

- Feb 5, 2012

- Messages

- 4,075

- Location

- Canada

- Vessel Name

- Northern Spy

- Vessel Make

- Nordic Tug 26

Tell me that left is UP, on the posted photo?

Otherwise the separator on the filter won't work!!!

The manual says :

Note -- mount the filter assembly as close to vertical (V) as possible. Do not

exceed 10o from vertical or the assembly may not function properly.

Look again.

Looks like it's sitting on the tailgate of a pickup truck.

If not, I'd be interested if the herringbone brick work is stock KK or added by the owner.