Skinny

Senior Member

Hey guys!

Been away for awhile trying to focus on employment as it truly is one of the only ways to get ahead in boat life

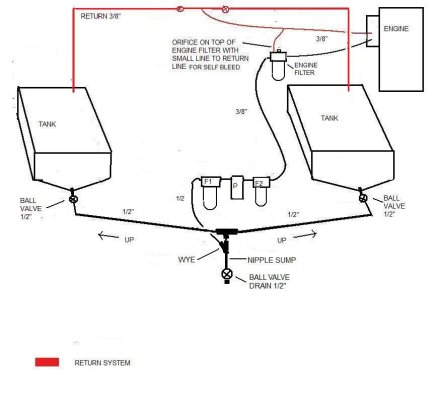

As spring is approaching, so is getting my fuel system replumbed before launch. I decided to get away from the polish capability. With two large filter sets and good additive, it sounds like an unnecessary complication and expense.

I do want to take everyone's advise and get the genset and propulsion separated out on dedicated feeds and returns. I think a set of 3 way valves will accomplish this. I can run either engine on one tank and switch over to another to manage fuel balance or if one filter set becomes plugged. I also can run the genset off the opposing tank underway if necessary.

Let me know your thoughts as everyone has awesome input so far!

Been away for awhile trying to focus on employment as it truly is one of the only ways to get ahead in boat life

As spring is approaching, so is getting my fuel system replumbed before launch. I decided to get away from the polish capability. With two large filter sets and good additive, it sounds like an unnecessary complication and expense.

I do want to take everyone's advise and get the genset and propulsion separated out on dedicated feeds and returns. I think a set of 3 way valves will accomplish this. I can run either engine on one tank and switch over to another to manage fuel balance or if one filter set becomes plugged. I also can run the genset off the opposing tank underway if necessary.

Let me know your thoughts as everyone has awesome input so far!