tegdesign

Senior Member

Newbie sanitation question:

I hope this story doesn't go on too long, but I want to get all the boring details incase some detail is unexpectedly important.

Bought the boat in November of 2014. Haven't gone on any extended trips so far so have not really used the black water tanks. But the PO didn't empty them before handing the boat over. I've been cleaning the bilge trying to eliminate a greasy odor which, so far I have not been successful at.

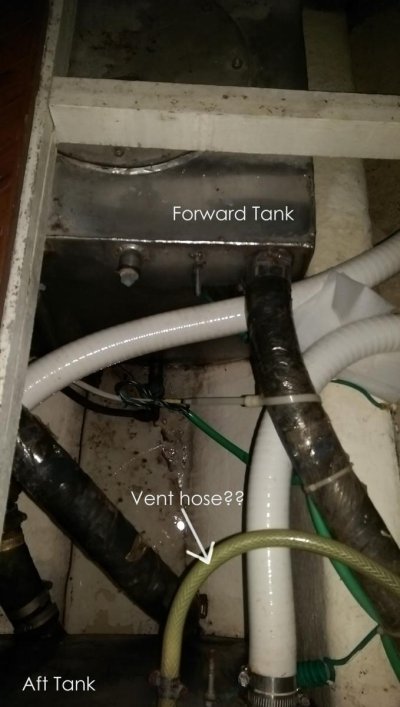

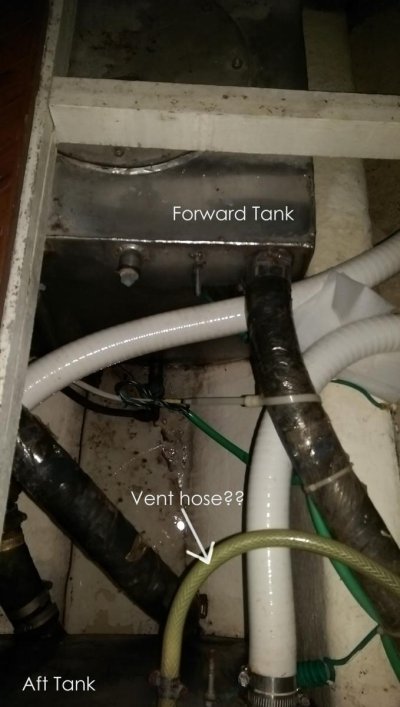

The tanks are Stainless Steel. The forward one has an accessible inspection port. The aft one is under a fixed deck and no obvious inspection port.

After pumping the tanks at a waste station and getting all the nasty water out of the bilges I noticed that the aft SS tank did not empty. It has a solid thudding noise when you bang on it where as the forward SS tank sound hollow and echoes. This gave me some things to consider. Is my venting clogged and not allowing the sludge to be sucked out? This full aft tank is the one the macerator pump is connected to. Not sure how this works in a situation where you would want to pump the forward tank overboard? But the macerator is not functional. I have a replacement pump ready to go, and would love to change it but wouldn't dare if the tank is full of coarse!

Since I haven't come up with a game plan I moved onto another project. In the meantime, I noticed that there is an inch of water in the bilge again under the waste tanks and a black residue floating around in it. It's not the freshest smelling either! Now I'm wondering if there is a leak in that tank?

So I'm wondering about how to proceed? I'm on a budget, so need to explore least expensive possibilities first. Looking forward to some input. Thanks!

I hope this story doesn't go on too long, but I want to get all the boring details incase some detail is unexpectedly important.

Bought the boat in November of 2014. Haven't gone on any extended trips so far so have not really used the black water tanks. But the PO didn't empty them before handing the boat over. I've been cleaning the bilge trying to eliminate a greasy odor which, so far I have not been successful at.

The tanks are Stainless Steel. The forward one has an accessible inspection port. The aft one is under a fixed deck and no obvious inspection port.

After pumping the tanks at a waste station and getting all the nasty water out of the bilges I noticed that the aft SS tank did not empty. It has a solid thudding noise when you bang on it where as the forward SS tank sound hollow and echoes. This gave me some things to consider. Is my venting clogged and not allowing the sludge to be sucked out? This full aft tank is the one the macerator pump is connected to. Not sure how this works in a situation where you would want to pump the forward tank overboard? But the macerator is not functional. I have a replacement pump ready to go, and would love to change it but wouldn't dare if the tank is full of coarse!

Since I haven't come up with a game plan I moved onto another project. In the meantime, I noticed that there is an inch of water in the bilge again under the waste tanks and a black residue floating around in it. It's not the freshest smelling either! Now I'm wondering if there is a leak in that tank?

So I'm wondering about how to proceed? I'm on a budget, so need to explore least expensive possibilities first. Looking forward to some input. Thanks!