Tunajoe

Senior Member

I just finished laying a few more areas of Amtico in my office tonight.

I thought I'd show a few pictures of the finished job and some closeups of the actual product in case any of you were curious about it.

As most boaters know, Amtico is used on interiors of quite a few boats instead of real wood. I know it's an option on the newer NT's.

It's a photo-realistic PVC flooring that you can order with a variety of features (such as beveled edges, ticking, 4.5" wide vs 6" wide, etc)

I've installed hundreds of square feet of it and I find it easy to install.

The most important thing is to make sure the correct subfloor is installed as the Amtico will show any bump or wave.

It's stuck in place with flooring adhesive. You can get 2 types; water based or 2 part epoxy.

I always use the epoxy adhesive as we can have tremendous temperature swings during the day and the epoxy essentially water proofs the install so we can wet mop the floor.

I'm sure for boats it's the same as a house or office and you'd want to use the 2 part epoxy.

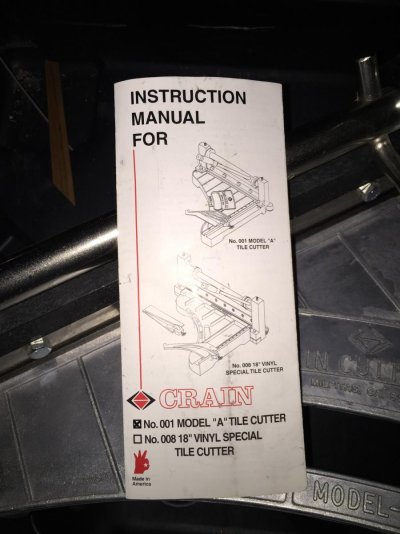

You do need a special cutting device in order to cut it to size.

The great thing about Amtico is that it wears fantastic. It's super durable, and is nice looking.

I installed 8 years ago in my dental operatories and it looks as good as the day I installed it.

I thought I'd show a few pictures of the finished job and some closeups of the actual product in case any of you were curious about it.

As most boaters know, Amtico is used on interiors of quite a few boats instead of real wood. I know it's an option on the newer NT's.

It's a photo-realistic PVC flooring that you can order with a variety of features (such as beveled edges, ticking, 4.5" wide vs 6" wide, etc)

I've installed hundreds of square feet of it and I find it easy to install.

The most important thing is to make sure the correct subfloor is installed as the Amtico will show any bump or wave.

It's stuck in place with flooring adhesive. You can get 2 types; water based or 2 part epoxy.

I always use the epoxy adhesive as we can have tremendous temperature swings during the day and the epoxy essentially water proofs the install so we can wet mop the floor.

I'm sure for boats it's the same as a house or office and you'd want to use the 2 part epoxy.

You do need a special cutting device in order to cut it to size.

The great thing about Amtico is that it wears fantastic. It's super durable, and is nice looking.

I installed 8 years ago in my dental operatories and it looks as good as the day I installed it.