Hi folks,

I've got a couple questions for you experienced and knowledgeable manatee owners.

My fuel gauge has never seemed to be 100% accurate. A few years go I replaced the tubing from the back of the gauge to the top of the tank and hoped that would resolve it but it seems that maybe the diameter of the hose is slightly larger and possibly affects the reading or there is a small air leak.

What is your folks experience? It seems a site gauge on the tank would be a better alternative. Has anyone had this issue and how did you resolve or improve on it?

I'm curious if others have had any issues taking on fuel on their Manatee. The horizontal run of the inlet hose to the top of the tank seems to be very easy to fill up if the fuel hose pressure is too much. I noticed that quite a while back so I'm always slow to take on fuel pumping and waiting a bit then pumping some more..

In the past in an attempt to get a better idea of the tank level I have disconnected the filer hose from the top of the tank and dropped a string with a nut tied to it until I heard it hit the bottom and pulled it right up to see where the fuel was on the string. I know the tank is not flat but at least I could get an idea of how far up the fuel was in it.

I keep a log on engine hours so I can guesstimate fuel consumption as well but I recently installed a new Webasto diesel heater and haven't been as good about tracking hours used so I can't estimate consumption as well.

I wanted to top off the tank cause I figured I'd been using the heater quite a bit but did it the poor mans way - a couple of 5 gallon jerrycans and a little Shaker Siphon hose. The first 10 gallons went in fine but the third one gurgled up a bit. It didn't splash out but I could hear it and then looked inside with a flash light and saw fuel. I wouldn't think the siphon was much pressure to cause the horizontal run to fill up so fast but apparently it did. My gauge of course reported 3/4 a tank so I'm not sure if I overfilled the tank or not.

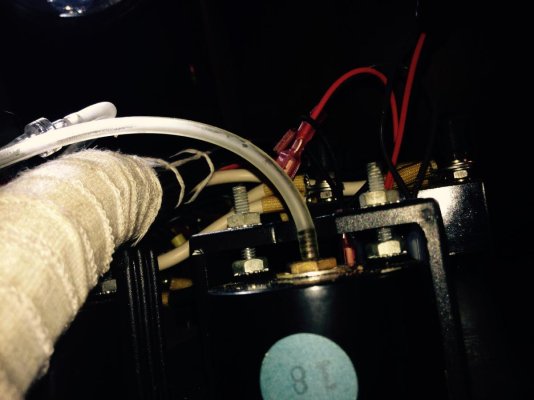

Today when I opened the hatches to go down and use the string method to check the level I noticed some diesel on the absorbent pad in the engine compartment bilge. I've never had that before so I immediately turned off the bilge pump, shut off the main on the fuel tank and I checked the hose run and fittings and hull but couldn't find a drop. Now I'm checking the filters and haven't been able to find a drop. Any ideas where this fuel could have escaped from? I'm wondering if I did overfill it would it have traveled back thru the return line? I'm hesitant to remove the hose from the top of the tank to check the level in case it spits some out until I have a helper around.

In the meantime I'm hoping some of you folks might have some thoughts to share. I'm due for a haul and wanted to schedule it this month but I'm at a standstill until I figure out what happened here and if there is anything else I should check or be concerned about in regards to the fuel system. Obviously this is critical to determine. My first concern was a tank seam leak but after placing absorbent pads and inspecting with a mirror and flashlight I didn't see anything on the underside of the tank (thank god) There was however a little fuel again on the new absorbent pad.

Any ideas are GREATLY appreciated.

I've got a couple questions for you experienced and knowledgeable manatee owners.

My fuel gauge has never seemed to be 100% accurate. A few years go I replaced the tubing from the back of the gauge to the top of the tank and hoped that would resolve it but it seems that maybe the diameter of the hose is slightly larger and possibly affects the reading or there is a small air leak.

What is your folks experience? It seems a site gauge on the tank would be a better alternative. Has anyone had this issue and how did you resolve or improve on it?

I'm curious if others have had any issues taking on fuel on their Manatee. The horizontal run of the inlet hose to the top of the tank seems to be very easy to fill up if the fuel hose pressure is too much. I noticed that quite a while back so I'm always slow to take on fuel pumping and waiting a bit then pumping some more..

In the past in an attempt to get a better idea of the tank level I have disconnected the filer hose from the top of the tank and dropped a string with a nut tied to it until I heard it hit the bottom and pulled it right up to see where the fuel was on the string. I know the tank is not flat but at least I could get an idea of how far up the fuel was in it.

I keep a log on engine hours so I can guesstimate fuel consumption as well but I recently installed a new Webasto diesel heater and haven't been as good about tracking hours used so I can't estimate consumption as well.

I wanted to top off the tank cause I figured I'd been using the heater quite a bit but did it the poor mans way - a couple of 5 gallon jerrycans and a little Shaker Siphon hose. The first 10 gallons went in fine but the third one gurgled up a bit. It didn't splash out but I could hear it and then looked inside with a flash light and saw fuel. I wouldn't think the siphon was much pressure to cause the horizontal run to fill up so fast but apparently it did. My gauge of course reported 3/4 a tank so I'm not sure if I overfilled the tank or not.

Today when I opened the hatches to go down and use the string method to check the level I noticed some diesel on the absorbent pad in the engine compartment bilge. I've never had that before so I immediately turned off the bilge pump, shut off the main on the fuel tank and I checked the hose run and fittings and hull but couldn't find a drop. Now I'm checking the filters and haven't been able to find a drop. Any ideas where this fuel could have escaped from? I'm wondering if I did overfill it would it have traveled back thru the return line? I'm hesitant to remove the hose from the top of the tank to check the level in case it spits some out until I have a helper around.

In the meantime I'm hoping some of you folks might have some thoughts to share. I'm due for a haul and wanted to schedule it this month but I'm at a standstill until I figure out what happened here and if there is anything else I should check or be concerned about in regards to the fuel system. Obviously this is critical to determine. My first concern was a tank seam leak but after placing absorbent pads and inspecting with a mirror and flashlight I didn't see anything on the underside of the tank (thank god) There was however a little fuel again on the new absorbent pad.

Any ideas are GREATLY appreciated.