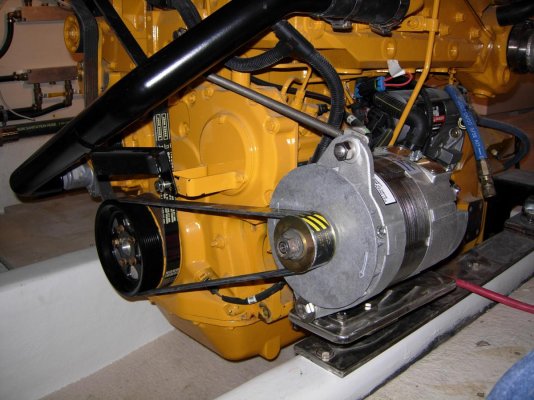

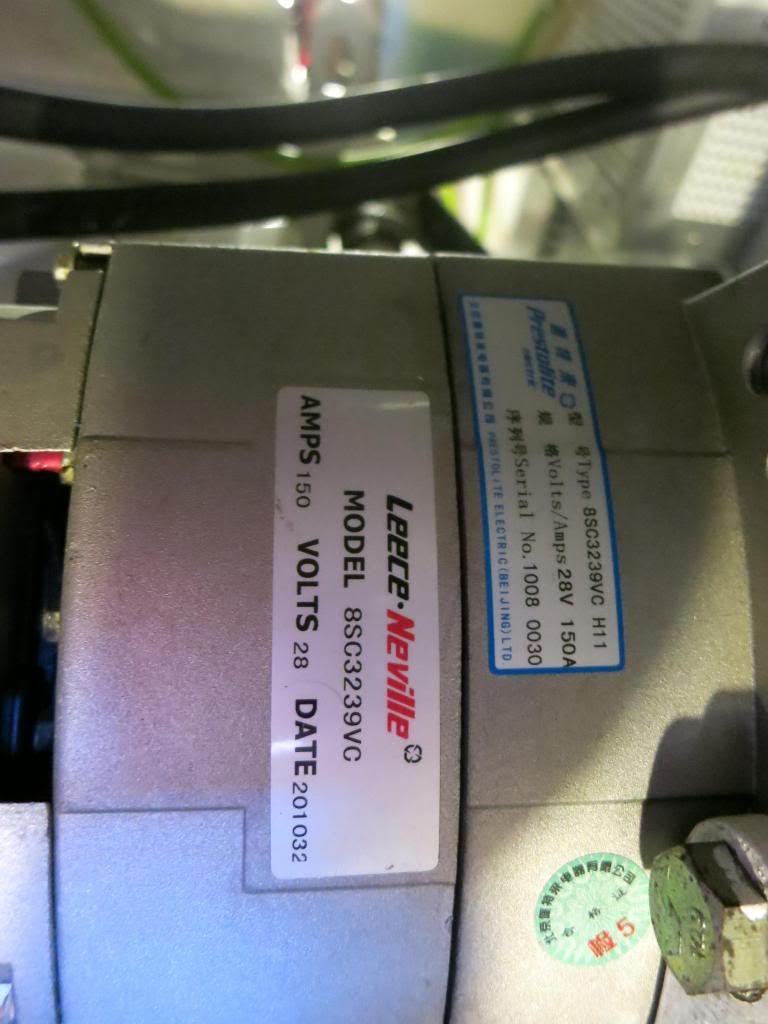

When doing the re-power on my trawler, setting it up with dual alternators like my charter boat was an obvious choice. First, if you are going to go to the effort of setting up dual alternators, don't just add one that's lying around or necessarily the same one as your stock engine alternators. Most stock alternators won't put out their rated amperage for very long. When they heat up, the output is reduced. On my charter boat I needed 120 amps out of the second alternator to run an AC unit. Originally I added a second 150 amp Delco alternator. When the unit got hot, it was barely able to maintain 110 amp output. Ended up switching it out to a 220 amp Leece Neville alternator and haven't had a problem since. The Leece Neville is a large frame truck alternator that is designed for continuous high output applications such as fire trucks and emergency equipment. The alternator is substantially larger and weighs maybe twice what the Delco weighs. For my trawler I decided to use the same alternator but added a 3 stage Sterling regulator as this alternator was more for charging the 900 amp battery back. On my trawler, the primary alternator is only for charging the engine battery as nothing else normally will run off it. All other loads run off the second alternator and the house battery bank. There is a battery switch that will tie the 2 banks together in the event of an alternator failure. The second alternator is mounted on a custom built front motor mount. Had to build motor mounts anyway, so this was a logical mounting choice. Because the second alternator has a quite large capacity, I decided to add a second pulley to the crank and have the second alternator driven by it's own 8 groove serpentine belt. Below are pics of the custom adapter between the 2 pulleys, the mounting, and belt tensioning rod (1/2" Stainless all thread). All brackets and hardware except for the pulley adapter are stainless steel.

View attachment 36548

View attachment 36550

View attachment 36557

View attachment 36551

View attachment 36554

View attachment 36553

View attachment 36555

View attachment 36556

If you think you need more than 220 amps, Leece Neville make this in sizes to over 500 amps. The mounting and diameter are the same, but the body gets longer and the price goes over $1K.

Ted