ralphyost

Senior Member

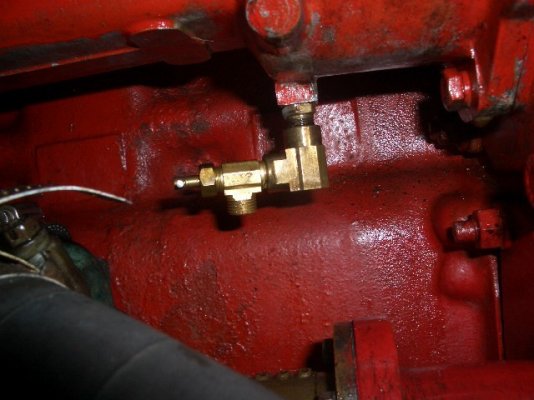

Looking for suggestions for a place to rebuild my fuel injection pump. Its a minimec pump off a 1982 Lehman 120.

The pump is leaking diesel into the lube oil, as is evidenced by the increasing lube oil level I measure when I change it. I have reduced the interval from 50 hours to 40 hours and its still exceeding the normal level.

One trawler buddy recommended Boston Injector. I called today and the owner told me my pump probably needs the valves to be replaced. Without looking at it, he ball parked an estimate of $900, possibly lower once he tears it apart.

Has anyone sent their injection pump to American Diesel (who will then send it out)?

Any any suggestions?

thanks

R.

The pump is leaking diesel into the lube oil, as is evidenced by the increasing lube oil level I measure when I change it. I have reduced the interval from 50 hours to 40 hours and its still exceeding the normal level.

One trawler buddy recommended Boston Injector. I called today and the owner told me my pump probably needs the valves to be replaced. Without looking at it, he ball parked an estimate of $900, possibly lower once he tears it apart.

Has anyone sent their injection pump to American Diesel (who will then send it out)?

Any any suggestions?

thanks

R.