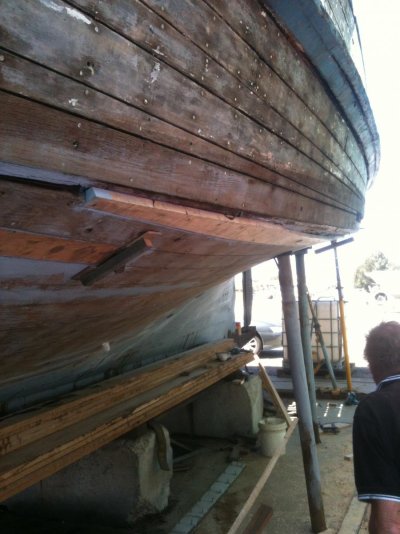

Big job

Wow what a big job. Having been down this road myself, I can remember only too well wondering if I was ever going to turn the corner from removing timber. On the subject of caulking, as you probably are well aware those planks are pretty dried out at this point. The problem for most of us is not having enough manpower to get a wood boat back in the water soon enough to keep them from drying out. If you caulk these seams tight in this condition you will probably end up with buckled planks once you splash, at the minimum you will have caulking squeeze out of the seams. In a perfect world it would be nice to splash the boat in slings for before caulking for several days if not a couple of weeks. Unfortunately it would be hard to find a yard that would do that for you. What I have done is wrap the hull with canvas painters tarps and used soaker hoses along the gunnel to wet the hull and keep it wet for several weeks before caulking. It's not perfect but it's better than not doing anything. If you don't have the manpower to move fast on the caulking you might consider focusing on the bottom below the waterline and splashing and finishing the hull sides in the water. Unfortunately one of the challenges of working on wood boats is time, they just seem to fall apart before your eyes as they dry out. A word of caution as you replace planks keep an eye on the fairness of your hull, wood boat are easy to distort with hull supports, you can't have enough supports in my mind. It looks like your doing a nice job, working part time makes a tough job even more difficult, I hope you enjoy the challenge, there are unfortunately many false summits on these projects, hang in there when your done you will have a truly unique vessel.