healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

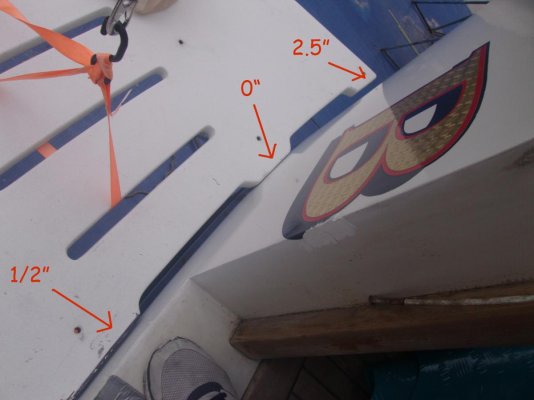

After years of getting quotes on new swim platform construction (4000-4500 bucks), I might have lucked-out on a used one. No, as far as I know there are no used Manatee swim platforms, but I kept looking at good take-offs at FL marine salvage places. It took three years, but I stumbled upon this one in Stuart and thought its radius might be very close. After measuring, it looked even closer, but it was way too big overall. I have to trim both ends but the radius was within 3/8" on four of the six inside touch points. The outside two I have to build up 2.5". The platform was 500. With any luck, I should be able to get this completed for 1 to 1.5 K including brackets. The source hasn't been able to learn what kind of boat it came off of, but condition is excellent.

This is a major part of our MOB rescue plan which included hand winches to replace blocks and tackle on davits, a pivoting dinghy crane, and another winch above the rear deck to attach and pull in someone like me, assuming my Admiral would stop to pick me up. The last step will be dividing the rear tailgate and hinging each half to swing inward.

This is a major part of our MOB rescue plan which included hand winches to replace blocks and tackle on davits, a pivoting dinghy crane, and another winch above the rear deck to attach and pull in someone like me, assuming my Admiral would stop to pick me up. The last step will be dividing the rear tailgate and hinging each half to swing inward.