Delfin

Grand Vizier

- Joined

- Jan 20, 2010

- Messages

- 3,820

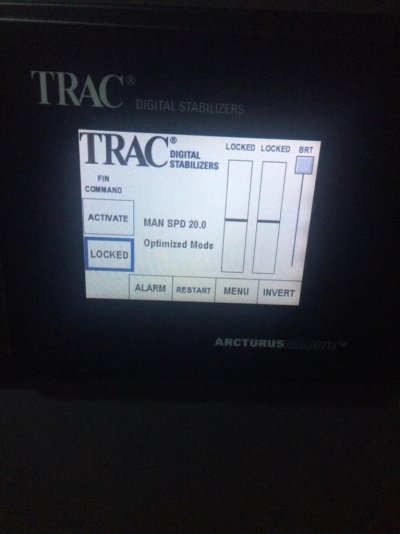

Tom, I presume the reason they don't move is the same reason the bucket on a front loader will stay raised when the hydraulics on the tractor are off. In that case, the position of the manual levers on the flow manifold (correct term?) aren't allowing any fluid flow. On stabilizers a three position servo valve with solenoids determine ram movement. Extend, retract and no flow are the options. The solenoids are normally closed so when you power down there is no flow and no movement for the reason you state. On our ABTs hitting the Center button moves the fins to the centered position and 3 way servo valve settles in the no flow position so the ram and the fins don't move. Go into reverse and if you haven't centered already a reverse sensor puts the servo valve into the no flow after centering the fins. If you hit "Restart" you hear a positive pin lock which is held normally open when the system is powered, and that solenoid depowers after centering so the fins cannot move, period.With our hydraulic pump off the fins do not move in a seaway nor do we pin them. I assume this is the case as liquids are incompressible. That said I will mark them accurately next time to be sure my statement is accurate to the nearest millimeter.

As far as what keeps the cylinder rams from moving when the system is off, I have never torn mine down, but I can only assume the system's valving or internal glands require pressure differential to allow piston travel which is the case in my industrial experience. A leaky or failed hydraulic cylinder requires a rebuild. Air actuated cylinders are a different story as pressure bleeds off under rest.

The only reason I can think of for the fins to be able to move is if the seals in the ram cylinder are allowing bypass, just as the bucket on a front loader will settle with its hydraulic cylinder seals are shot.

Hollywood, how old was the system on the 57 you said would move when depowered and if not pin locked?