Delta_JimS

Senior Member

- Joined

- Dec 15, 2012

- Messages

- 278

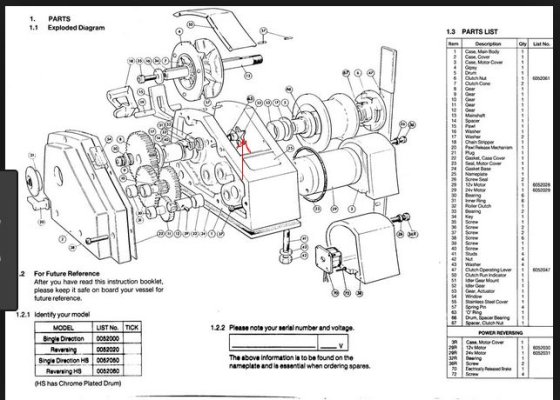

While we are on the subject of S - L Windlasses, has anyone (a good) experience with rebuilding the old (30 yr.) electric Seawolf, or at least replaced the main shaft bearings?

Mine was sounding like an old corn cob grinder when I first used it. I tore it down for inspection and found that the main bearings were shot. I cleaned up and greased everything as best I could. As I recall, the other gear bearings seemed OK, just the open main shaft bearings were all rusted out.

I have half-heartedly looked around for replacement bearings for this windlass because in spite of the horrible grinding noise, she works quite well a hauling up 100' of chain. I do not use it much and keep it covered now, so I suspect her state is stable.

I ran across this website about rebuilding the Seawolf and accept the fact that I should at least acquire the parts to do so sooner than later in any case: Dissecting and Repairing the Windlass on our Prout Catamaran

He mentions main bearings available from Motion Industries - Keeping Industry in Motion

which when I looked up are quite reasonable at $12.

I had also reviewed the site mentioned in Scotland who bought up all remaining parts, I guess. Homepage | Simpson Lawrence Yacht Parts & Spares

Looks like for now you can get most anything you need, but between the Euro conversion and air freight its pretty pricey. Might be nice to get any "wear" parts now while they are available.

I have put this off for 2 years because I clearly recall the horrible job it was the first time, including breaking off a stud that had to go to the machine shop for removal.

Would really appreciate any words of experience and/or other leads on where to get bearings or misc parts for this windlass.

[FONT="]Thanks in advance.

[/FONT]

Mine was sounding like an old corn cob grinder when I first used it. I tore it down for inspection and found that the main bearings were shot. I cleaned up and greased everything as best I could. As I recall, the other gear bearings seemed OK, just the open main shaft bearings were all rusted out.

I have half-heartedly looked around for replacement bearings for this windlass because in spite of the horrible grinding noise, she works quite well a hauling up 100' of chain. I do not use it much and keep it covered now, so I suspect her state is stable.

I ran across this website about rebuilding the Seawolf and accept the fact that I should at least acquire the parts to do so sooner than later in any case: Dissecting and Repairing the Windlass on our Prout Catamaran

He mentions main bearings available from Motion Industries - Keeping Industry in Motion

which when I looked up are quite reasonable at $12.

I had also reviewed the site mentioned in Scotland who bought up all remaining parts, I guess. Homepage | Simpson Lawrence Yacht Parts & Spares

Looks like for now you can get most anything you need, but between the Euro conversion and air freight its pretty pricey. Might be nice to get any "wear" parts now while they are available.

I have put this off for 2 years because I clearly recall the horrible job it was the first time, including breaking off a stud that had to go to the machine shop for removal.

Would really appreciate any words of experience and/or other leads on where to get bearings or misc parts for this windlass.

[FONT="]Thanks in advance.

[/FONT]