I have the Borel temperature alarm bands that wrap around the wet exhaust, on both propulsion engines and on my genset. I also have a full set of gauges on the genie: water temp, oil pressure, volts, hertz & genset start battery volts. I do look at the gauges every now and again on the rare occasions the genset is running for any length of time.

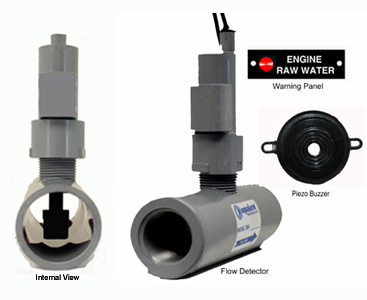

Wet Exhaust Temperature Alarm by Borel Manufacturing Inc.

Wet Exhaust Temperature Alarm by Borel Manufacturing Inc.