Just a quick update:

It looks like time is now my big enemy. What started as a electrical and charging system upgrade morphed into three other semi-major projects that required more time (due to back-and-forth trips, test fits, and other challenges) than anticipated. Not to mention the cost have gotten a little high and I need to recover from them.

That said, Now that I have a new raw water system and battery tray that will hold up to seven batteries (once I fix a minor screw-up), I plan to sort of prop up my old charging system for the early part of this season. I dread spending all this time on projects that are supposed to enhance the boating season, then feel the pressure and some guilt if it causes the loss of any possible boating enjoyment.

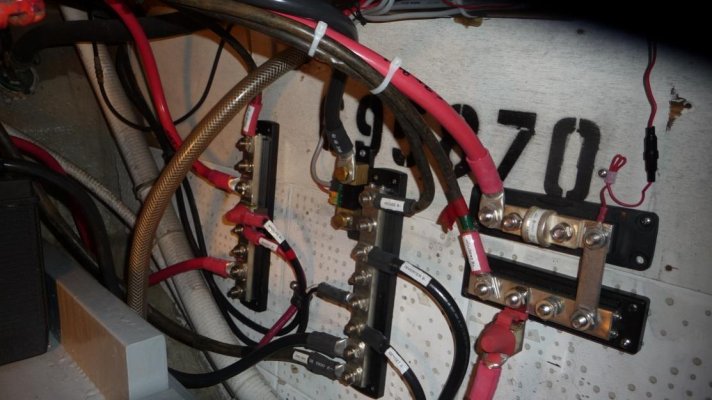

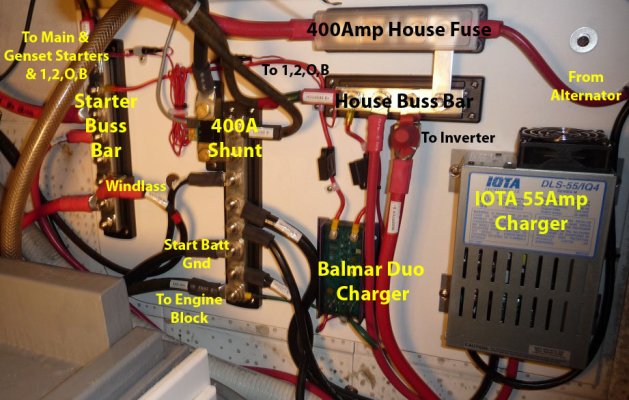

My plan is to clean up all the connections with new high quality lug connectors and the addition of HD Blue Seas battery switches in the lower step for on/off and battery combine. I think that I can take small steps toward the goal over the summer by adding more buss bars, the new Iota charger and heavier wire runs. Besides that, I tested the batteries with a 130A load tester and they came up "Weak", so I will need to gather the cash to replace them too.

In the meantime, I have some wire samples on the way from Harbor Specialists so I can see the quality and decide what connectors I need to order from Grainger. I also really need to crack open the fuel tank access plate and try and clean the sludge out sooner rather than later. So for the time being, the big wonderful project upgrades will have to wait. I just didn't expect the raw water rig to take so long AND that I would need to build a new battery tray. Oh well... trying to learn patience these days and this is my first test of what I have learned.

For now, here is the new battery tray all epoxied and painted and ready to go. :-D (measure 50 times... cut once... and STILL make it 1/2" too short! Dammit!)

tray

tray by

GonzoF1, on Flickr