DIY Sanitary Hose:

I finally got around to removing one of the dumbest things the PO did to my boat:

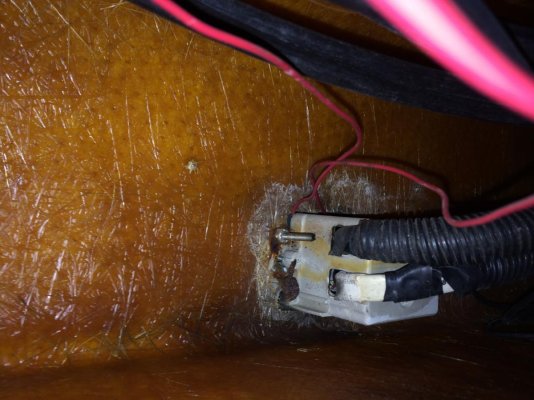

This was the hose coming from the forward head toward the holding tank. Look closely. That's red automotive RADIATOR HOSE the PO had painted white to make it LOOK like sanitary hose.

The adapter on the right attached to a piece of real 1-1/2" sanitary hose, which (except for one splice near the middle) went to the holding tank.

Oh, and that hose went UP through the bulkhead, then sagged DOWN along its way back up to the top of the holding tank, thus guaranteeing that it always remained full of waste water.

Last week I removed the vacuum cleaner hose the PO had connected to the shower drain. You can't make this stuff up!

I finally got around to removing one of the dumbest things the PO did to my boat:

This was the hose coming from the forward head toward the holding tank. Look closely. That's red automotive RADIATOR HOSE the PO had painted white to make it LOOK like sanitary hose.

The adapter on the right attached to a piece of real 1-1/2" sanitary hose, which (except for one splice near the middle) went to the holding tank.

Oh, and that hose went UP through the bulkhead, then sagged DOWN along its way back up to the top of the holding tank, thus guaranteeing that it always remained full of waste water.

Last week I removed the vacuum cleaner hose the PO had connected to the shower drain. You can't make this stuff up!