Who wrote the operators manual for the Lehman? Lehman? Why do you suppose it specifies 850rpm?.

The engine specs were written by Ford of England, who designed and built the engines. The manuals that boaters have were written by Lehman of New Jersey, which is the company that took the Ford diesels and designed and had fabricated the marinization kits for them. Thus "Ford Lehman." The engine specs in the Lehman manuals were simply lifted from the original Ford manuals.

But we're talking two different engines here, Eric.

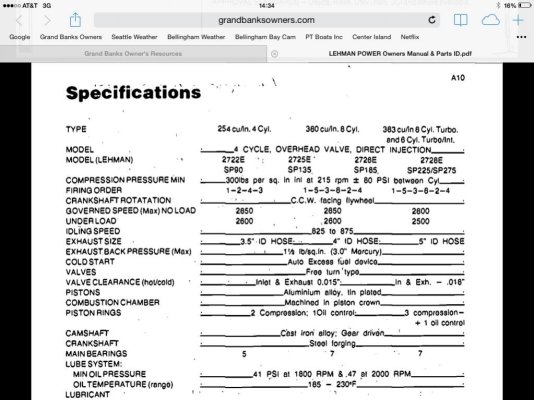

The original poster has Ford Lehman 135s, which is a marinized engine based on the Ford of England 135hp Dover diesel engine. This is the engine whose manual calls out an idle rpm of 825-875.

The engines I have in my boat are the earlier Ford Lehman 120s, which are marinized versions of the Ford of England 120 hp Dorset diesel engine. The manual for this engine specifies an idle rpm of 600-700.

While the Dorset and Dover diesels are similar in basic layout, they are not the same engine, hence the different horsepower ratings. The 120 hp Dorset engine was designed in the late 1950s. I'm not sure when the 135 hp Dover engine was designed, but my guess would be the late 1960s or even early 1970s.

The 120 hp Dorset was marinized by Lehman (and a lot of other companies around the world) in the mid-1960s. I don't know when Lehman marinized the 135 hp Dover engine, but my guess it was sometime in the later 1970s. Bob Smith at American Diesel would certainly know, as he worked for Lehman during this period.

So it's easy to confuse the two, but they are distinctly different engines from different time periods.

Trivia of the day: The British like to name things. They're the ones who came up with the name "Mustang" for the P-51, not us. Rolls Royce names their turbofan aircraft engines after British rivers. Ford was not so creative with their diesel engines. As I understand it, the 120 hp Dorset and the 135 hp Dover were named for the Ford of England engine plants where the engines were designed and manufactured.