the getaway

Veteran Member

- Joined

- Nov 17, 2012

- Messages

- 28

Figured I'd start a new thread. I'm installing 2 self contained units after my one self contained died from low voltage compressor failure. While I was researching my ancient split unit has finally gone to the grave. It lasted for 35 plus so no complaining here, oh wait, why did it have to go NOW

I'm installing 2 16000 webasto cause I'm cheap and they looked pretty decent after all my research and they were cheap.

Now the Questions! I read on another thread about using wrapped insulated 4" pvc instead of the usual flexible hose because of greatly improved air flow and cooling. Anyone else try this? How big of a pain is wrapping and then trying to maneuver rigid pipe through tight spaces and cabinets? If it's worth it I'm all for the extra effort, just would like to know before i buy/start.

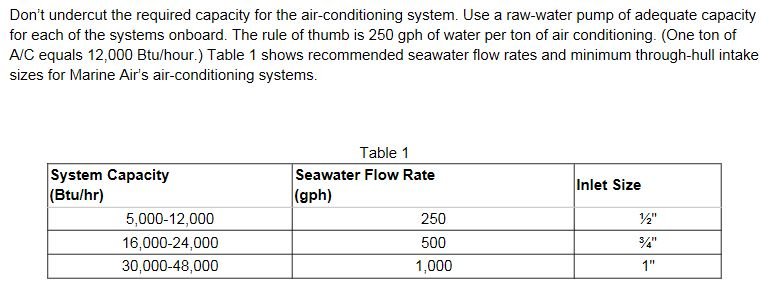

I have a March 1020 gph pump servicing both AC's now, but they are 5' apart. The salon AC is just a remove and replace and add an extra vent to the aft cabin. The split system cooled the aft and v berth. So now the other unit will go beneath the v berth and run new duct to the galley, front bathroom, and v berth. I'm hoping this is enough going to the aft as the split unit was crappy and it cooled ok until it gets really hot out. Anyhoo, is that pump still going to be able to service both units as the v berth is 20-25 feet away from the pump now? I have a bad feeling that more money is coming out of the down island fund.

I've got more questions but that last thought has me woozy!

Thanks

I'm installing 2 16000 webasto cause I'm cheap and they looked pretty decent after all my research and they were cheap.

Now the Questions! I read on another thread about using wrapped insulated 4" pvc instead of the usual flexible hose because of greatly improved air flow and cooling. Anyone else try this? How big of a pain is wrapping and then trying to maneuver rigid pipe through tight spaces and cabinets? If it's worth it I'm all for the extra effort, just would like to know before i buy/start.

I have a March 1020 gph pump servicing both AC's now, but they are 5' apart. The salon AC is just a remove and replace and add an extra vent to the aft cabin. The split system cooled the aft and v berth. So now the other unit will go beneath the v berth and run new duct to the galley, front bathroom, and v berth. I'm hoping this is enough going to the aft as the split unit was crappy and it cooled ok until it gets really hot out. Anyhoo, is that pump still going to be able to service both units as the v berth is 20-25 feet away from the pump now? I have a bad feeling that more money is coming out of the down island fund.

I've got more questions but that last thought has me woozy!

Thanks

Last edited by a moderator: