MARIN: Are you suggesting that the tang can't handle the 1" Johnson pump?.

The tang is not a factor with the Johnson pump conversion.

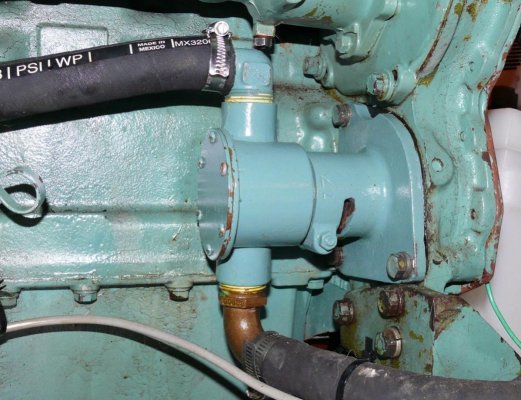

When an FL120 is converted to the one-piece Johnson pump, the Johnson pump replaces BOTH the drive coupler AND the Jabsco pump. So the entire, two-part origional system goes away. The Johnson pump mates to the same gear in the engine's accessory case that the Lehman drive coupler mated to.

With regards to the longevity of the drive tang on the Lehman drive coupler, there is no telling how long one will last before it cracks and breaks.

Our engines had about 2500 hours on them when a leaking raw water pump on the port engine prompted pulling the pump to rebuild it. I had replaced the impeller and the seals but the pump still leaked so it obvously had a more complex problem. When the shop removed the Jabsco pump, they saw that the drive tang on the Lehman drive coupler had cracked almost all the way through and was starting to deform. It was very close to breaking altogether with about 2500 hours on the clock.

This is what prompted us to switch to the Johnson pump. Since we were doing one engine, we figured we might as well do both of them. When the shop removed the starboard pump and drive coupler, they found that the tang on that drive coupler was just fine. So we kept that coupler and its Jabsco pump as a spare raw water pump system should we ever need it.

Which goes to show that the longevity of the drive tang on a Lehman drive coupler is anyone's guess. They may go for many thousands of hours with no problems at all, or they may crack and break in a couple thousand hours.

As I mentioned, Bob Smith at American Diesel designed the coupler when he worked for Lehman, and he told me that it was very difficult to manufacture. He also told me that the drive coupler was the only component of the FL120s marinizatoin kit to have ever had a factory recall. He told me the design made sense at the time, but in looking back on it he would have come up with a different design.

He said the attempted fix to a cracked or broken tang is to weld it back together. According to him, this fix is short-lived at best.

Converting to the Johnson pump elimates the potenttial problem altogether, and is one of the four best mods Bob feels can be done to an FL120.

The Johnson pump recommended for the FL120 is the 3/4" pump, The pump recommended for the FL135 is the 1" pump. However, the 1" pump will fit on the FL120, and it gives an increased water flow over the 3/4" pump. This makes no difference to the engine temperature, which is controlled by the thermostat. But it does make a significant difference to the transmissions, which on our boat run noticeably cooler than they did with the original setup. And anything that helps a transmission run cooler is a good thing to my way of thinking.

Photo is the 1" Johnson pump on our port engine.