I'd like to vote for gore packing as well, but I also don't want to make the mistake I see going on here in this thread where we talk about packing and not about principles. If you can't get good ole flax/wax impregnated packing to work, that's not a reason to change packing to gore or a dripless seal or anything else. That's a reason to get back to basic principles and solve the real problem.

First off, I also agree with someone else who mentioned that you don't want to over tighten and then back off until it drips. Packing does not easily re-orient itself once tightened. The only chance you have to make that work is to completely back off the nut and then strike it with a hammer while rotating to try to beat it back, then start the tightening process again. In your case, since you have "goo", which is melted wax already oozed out of the nut, start over. The waxy material is a part of the lubrication process. When typical flax overheats, it becomes hard and brittle, if you tighten hard/brittle material you simply make it into sandpaper and will score your shaft.

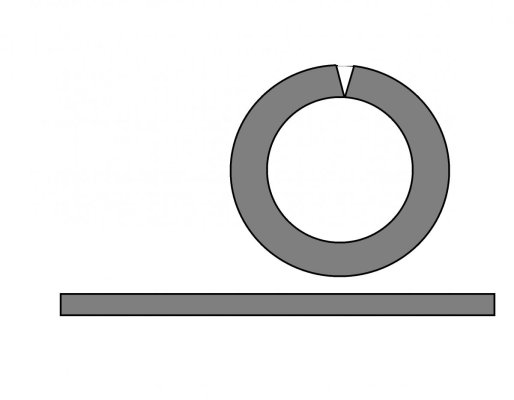

But again, back to basic principles. Lets start a visualization here. Go get your portable drill and carefully put a drill bit into it nice and straight and then hit the trigger. Wait...you DO have at least one decent drill bit and a portable drill don't you? If not, that's a red flag, but lets move on. If you watch the sides of the bit while turning, you basically should still see the shape of the drill bit as when you started. It should appear to be the same width as when its not spinning. Okay, now lets reset the bit in the drill, but this time intentionally load it not quite centered into the chuck. Now spin the bit. You should notice that while spinning the bit appears to be much wider than it really is. It's not spinning perfectly centered, so creates the impression of a much wider drill bit. What I'm getting at here is that packing only works if your shaft is turning true. If it is not, its just like that off centered drill bit. When turning, it wants to assume a shape that is much wider than the width of the shaft. The packing then tries to form a shape around that perceived wider shaft. In my experience, most folks don't pay all that much attention to cutless bearings, alignment, shaft straightness until forced. Yet, the packing can only work if that entire running gear system is in good shape.

Lets take another look at packing now assuming that we really don't know the condition of your running gear. Lest you think you can eyeball it, you can't unless your eyes can see down to 2 thousands of an inch, cause that's the degree to which shafts are typically aligned. At rest, packing can easily be tightened down to no dripping because the width of the shaft is fixed. When running, there will be some degree of expansion of the perceived width of the shaft. This basically causes the packing be be beaten back and leaves a hole by which the packing will allow leakage. Once at rest, the packing swells back up and the dripping should typically stop. While there is some ability to handle a little misalignment, its not much. If you can't get flax packing down to less than 4 or 5 drips a minute, heck even double or triple that is not the end of the world. What it means is that your shaft alignment is not true. It can be caused by any of the components in your running gear (shaft true, cutless bearing wear, coupling alignment, strut alignment, prop out of true).

So, the procedure is to put packing into the stuffing box, then to just tighten until you slow down the dripping at rest, let it sit for the packing to swell and then tighten again just until you again see it taking effect to slow dripping down to just a few drips. No need to tighten it completely, especially since backing it off is not so easy. Then go out and run it. Incrementally tighten no more than maybe 1/8 to 1/4 turn at max, then run for awhile. Each time, monitor both the drip rate as well as the heat. You arrive at a point where either the dripping gets within an acceptable range, or you notice that the dripping remains the same while the heat goes incrementally higher. At that point, you pretty much know whether its going to work or not. The stuffing box will get warm, but should never get really hot. If its hot enough to melt wax at any level, that's too warm. That's a symptom not of bad packing, but of bad running gear. While its pretty typical to have more dripping while running than at rest, if there is a big difference in drip rate, that's telling you right away that your packing is getting beaten back to a larger diameter due to the spinning shaft. You will want to really watch the spike in temperatures in that condition as you tighten the packing incrementally while suspecting you just may not be able to get the stuffing box to seal in an acceptable fashion.

Yes, you can try "better" packing materials than standard flax. They are more resilient and can take more heat. With a decent state of running gear the gore packing is dripless without undue heat, but you will waste your money to think that going to better packing will take the place of a running gear misalignment. Worse, it may allow you to ignore and otherwise not notice a very real problem worth solving. Flax packing has a major advantage of being a canary in a coal mine.

Its tempting to just monkey see/monkey do and go straight to the miracle product, and there are lots of good reasons why doing so is not necessarily a bad thing. I just encourage you to take enough time to make sure you really know that packing is your issue, as we are all pretty guilty of recommending our individual wonder products (I certainly have my own) when we should be wondering aloud why an acceptable result can't be achieved without such wonder products.

Lastly, my personal pet peeve, slightly askew to your issue. Never take the arm chair advice to tighten a packing gland as the solution for dripping packing UNLESS you know the precise state of the packing within that gland. I always see people jump straight to "tighten the gland" to stop a drip. The problem of course is if the packing has been overheated, tightening will ruin the shaft in short order where otherwise you have the option of replacing ten bucks worth of packing first. A scored shaft may not drip at rest, but will never fully seal running because it is not true. Of the last three boats I've owned, each came to me with packing that was a bit dry & brittle. I would not have wanted to tighten those without knowing the state of the packing, and the only way I know to do that is to pull it out. It may not be enough data points to come to a perfect consensus, but enough for me to realize that in many cases, blindly tightening a packing gland is the wrong solution and will cause more problems that it solves. Will those making the blind armchair recommendations be there to help haul the boat just so you can change the length of your shaft log to get on some clean shaft material? In most cases, probably not and that's why it gets me so riled up to monkey see/monkey do that kind of advice.