fryedaze

Guru

- Joined

- Sep 4, 2011

- Messages

- 1,722

- Location

- USA

- Vessel Name

- Fryedaze

- Vessel Make

- MC 42 (Overseas Co) Monk 42

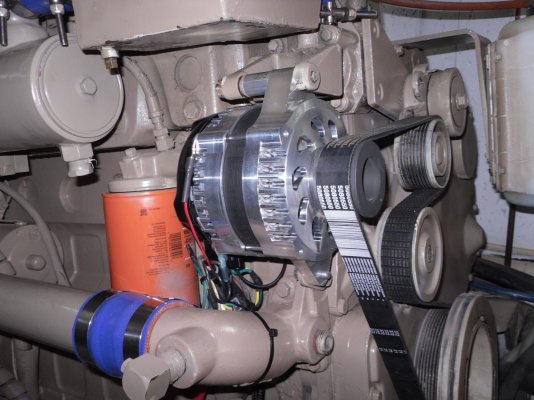

In search of ideas to solve my belt slip problem. I have a 120/150 amp alternator on both my 1989 Cummins 6BT5.9Ms. This is a recent upgrade from the old 55 amp alts. The problem is the belts are slipping when the alts load up. I have checked the alt, water pump and tensioner for free movement. The belt in the picture is the first belt I put on that slipped. I bought another belt that didnt have the segments in the grooves and it did the same thing. I can see the slipping in the tach response. My research says that the serpentine belt I have should easily handle 120 amp load on the alt. Looking for a little old TF help.

![images[1].jpg](/data/attachments/28/28434-a7f31fbded8b1a9dc2dae218e8083bb2.jpg)

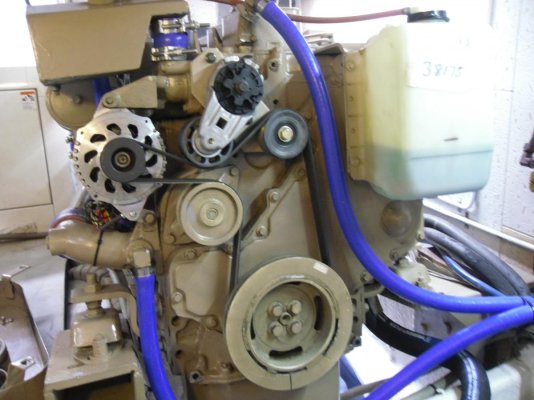

![images[5].jpg](/data/attachments/28/28435-ca2cd201b2769412d4a19d0e8556209c.jpg)

The belt guard didn't fit with the new tensioner location. So it was back to the house for cutting bending and paint. I suspected this would happen. Shes done done now.

The belt guard didn't fit with the new tensioner location. So it was back to the house for cutting bending and paint. I suspected this would happen. Shes done done now.