LaBomba

Guru

- Joined

- Nov 18, 2012

- Messages

- 1,240

- Location

- Canada

- Vessel Name

- Looking Glass

- Vessel Make

- Carver 370 Voyager

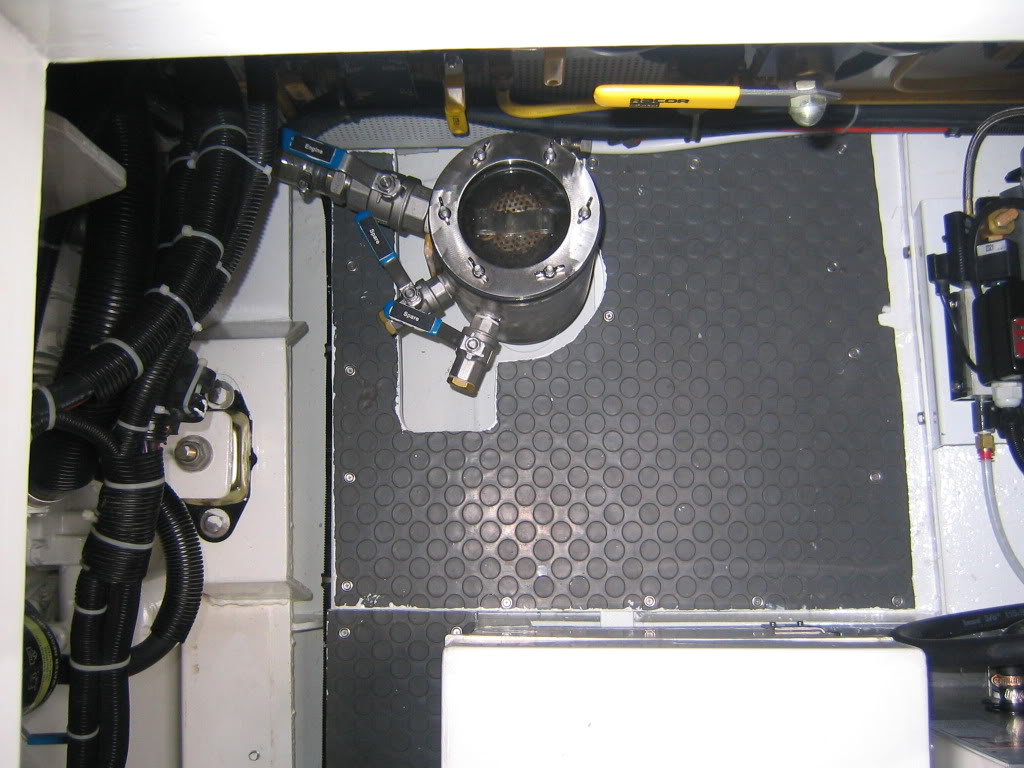

One of the projects on my list before splash this spring was to install a Perko raw water strainer since the Volvo plastic basket strainer is not transparent and must be disassembled to see that it has nothing in it. Since all the hoses on the boat were replaced by the PO as a requirement of the insurance company due to the survey when he purchased her, I thought this would be straight forward. One thing that I did notice was that there were only single clamps on all fittings below the water line and that all clamps were perforated. Since I was going to add a clamp anyway I would change them to non perforated and double up. Well when I took off the raw water hose much to my surprise was a pipe nipple not a hose barb and not long enough for a double clamp. I mentioned this to the marina mechanic and he indicated that this was very common in older boats. Well I fixed it regardless. Are there any other issues in older boats that may have been ok at the time but not acceptable in this day and age??? Would this worry you?