Fotoman

Guru

- Joined

- Nov 12, 2009

- Messages

- 649

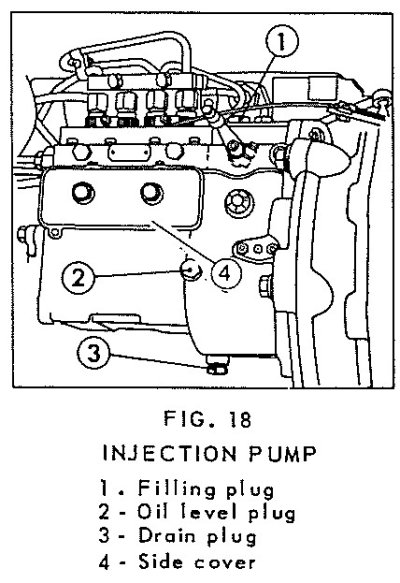

Last night I decided to change the oil in the injection pump. According to the manual, it should be changed every 50 hours or so.

I had 2 issues:

First, the pump I have does not match the diagram in the manual (see pictures). There is no drain plug at the bottom on my pump. It looks like it's on the side (C) and that the level plug is also on the side but in the rear of the pump (B). This would make some kind of sense*since bolt B is*higher than bolt C. The filler plug (A) looks like it's at the right place. But there is a little plastic cover beside it (D) that is mysterious. Tried to remove it gently but didn't succeed.

The second issue I had is a bit more worrying. When I removed the 3 bolts, no oil came out! Not a drop. Could it be that there is a leak somewhere and that the level of the oil is so low it's under the drain plug? Am I missing something here?

I decided to put everything back together and seek advice before I use the engine again. Any input would be appreciated.

-- Edited by Fotoman on Wednesday 23rd of June 2010 07:17:03 AM

I had 2 issues:

First, the pump I have does not match the diagram in the manual (see pictures). There is no drain plug at the bottom on my pump. It looks like it's on the side (C) and that the level plug is also on the side but in the rear of the pump (B). This would make some kind of sense*since bolt B is*higher than bolt C. The filler plug (A) looks like it's at the right place. But there is a little plastic cover beside it (D) that is mysterious. Tried to remove it gently but didn't succeed.

The second issue I had is a bit more worrying. When I removed the 3 bolts, no oil came out! Not a drop. Could it be that there is a leak somewhere and that the level of the oil is so low it's under the drain plug? Am I missing something here?

I decided to put everything back together and seek advice before I use the engine again. Any input would be appreciated.

-- Edited by Fotoman on Wednesday 23rd of June 2010 07:17:03 AM