Eric, Gallery Marine was responsible for the botched repower in '07.

My just finished experience with Townsend Bay Marine in Port Townsend was excellent. They are the first yard I have ever dealt with that was 1). reasonably priced ($60/hour), and 2). completely competent. They prepared an estimate of the likely cost of the work that needed doing (cutlass bearings, bottom paint, prop work, PYI shaft seal maintenance, thruster and fin servicing) and hit it pretty much on the nose even though I added some things and didn't do some things I thought needed doing based on their recommendations. They took pictures of everything they touched, and prepared a 1 1/2 page commentary on things to think about. They noticed and commented on a number of open issues. For example, bow thruster port and starboard props reversed (happens about 50% of the time, they say), engine out of alignment (unexpected, since I have paid two other yards twice to do precisely that but it clearly has never been done correctly), noted that one of the floor boards in the E/R was in contact with the shaft, etc.

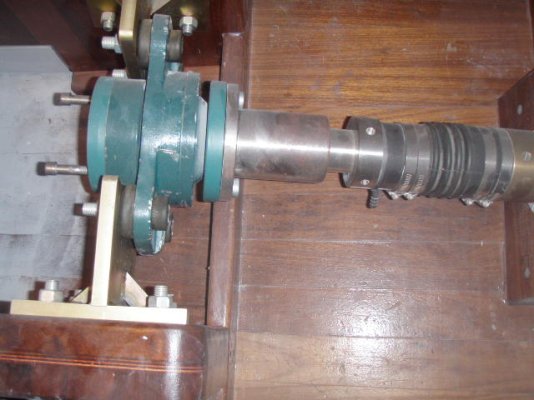

In addition, when we found that the i.d. of the stern tube was some weird metric (built in Norway in 1965) while the cutlass bearings were 15 thousand bigger, the manager took them home to his shop and turned them to fit.

Another upside is that the lifts are owned and maintained by the Port of P.T., meaning they are in great shape with very professional operators. Great experience.

Downside - like all boat yards the amount of dust and crud you collect in 10 days on the hard is hard to believe. Took me 4 hours to clean it all off. But I am not complaining and this would be my first recommendation in the NW for a yard.

Were I installing an aqua drive, these would be the first guys I would talk to.

![foto[3].jpg](/data/attachments/27/27293-1aab42cbe7b68bef613950e9732001c7.jpg)