Dixie Life

Senior Member

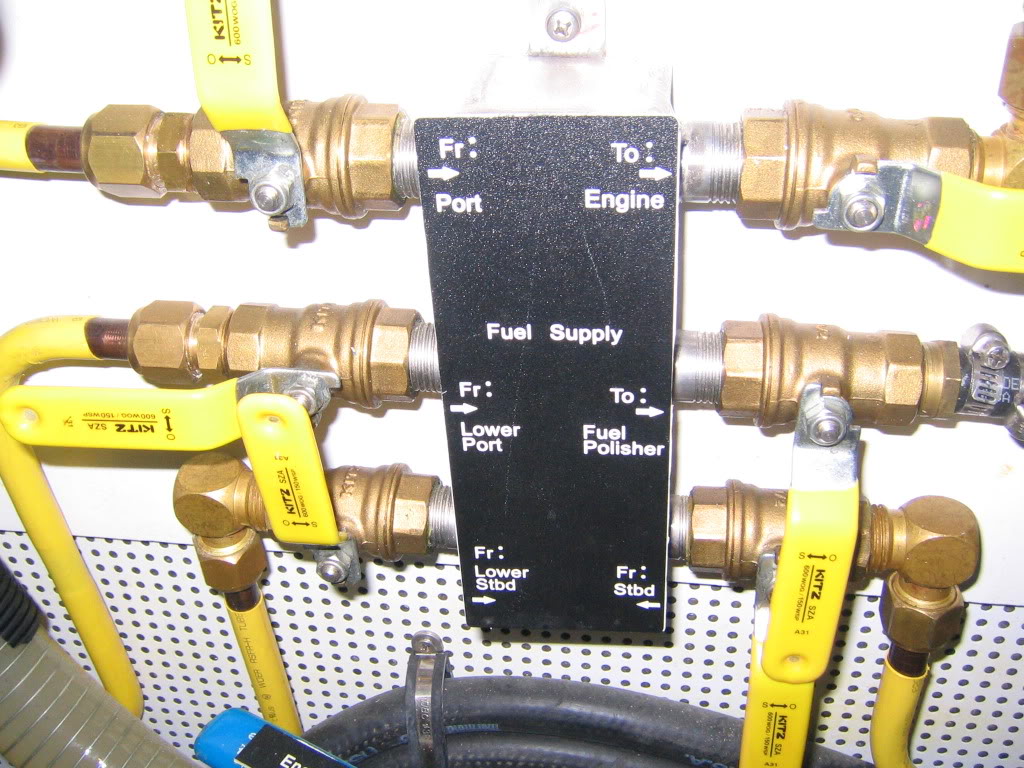

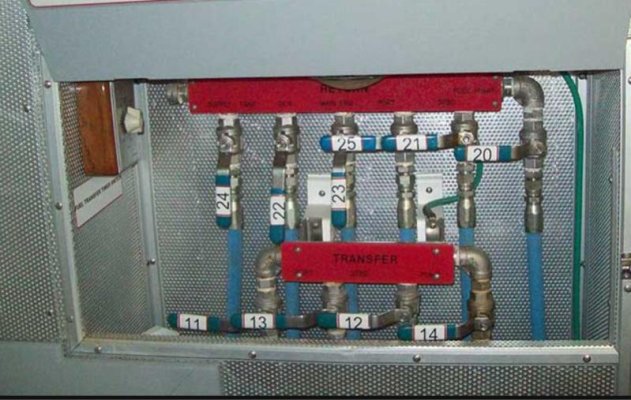

I'm getting ready to install a Racor dual filter in place of my single. The fuel lines are all copper. Rather than dealing with cutting/flarring my plan is to replace all lines with rubber and barb fittings. Copper is probably a much better system; but I also intend on changing shutoff valves, etc.. Barb/rubber will save me a ton of labor. Eager for any advice before I dive in.