Tony B

Guru

- Joined

- Jul 18, 2011

- Messages

- 1,251

- Location

- Cruising/Live-Aboard USA

- Vessel Name

- Serenity

- Vessel Make

- Mainship 36 Dual Cabin -1986

I have an older (1994?) Seaworthy Dinghy which were sold by West Marine way back when.

I have the 10' one which I think measures out at 9' 6".

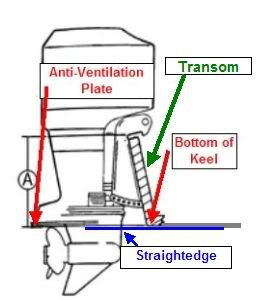

My transom height is just under 15". It really needs to be about 17" for my O/B motor.

I want to add about 2 1/2" t0 3" to the height of my transom without doing a major transom rebuild.

My idea is to fabricate an aluminum plate about 12" high, 20" wide and 1/4" thick. and bolt it on from the outside. Then bolt some plywood to it on the inside above the existing transom top so I can attach the 90 lb. Tohatsu O/B to it.

Will 1/4" aluminum plate be too thin? Should I use steel and paint it?

has anyone else conquered this problem yet?

Thanks in advance.

I have the 10' one which I think measures out at 9' 6".

My transom height is just under 15". It really needs to be about 17" for my O/B motor.

I want to add about 2 1/2" t0 3" to the height of my transom without doing a major transom rebuild.

My idea is to fabricate an aluminum plate about 12" high, 20" wide and 1/4" thick. and bolt it on from the outside. Then bolt some plywood to it on the inside above the existing transom top so I can attach the 90 lb. Tohatsu O/B to it.

Will 1/4" aluminum plate be too thin? Should I use steel and paint it?

has anyone else conquered this problem yet?

Thanks in advance.