Must be the season for exhaust elbows.

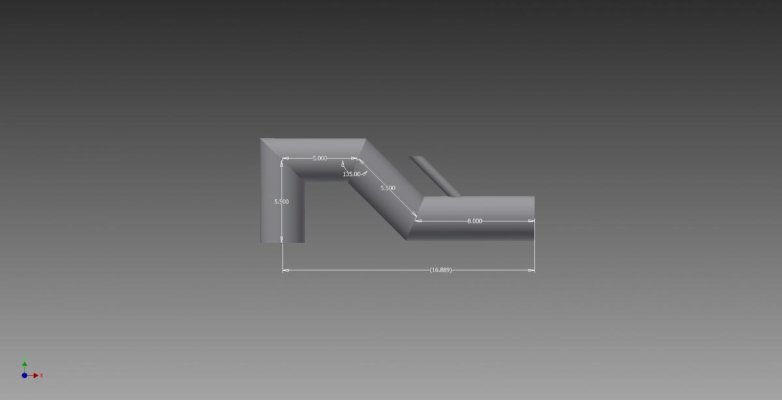

Anyhow, i need an exhaust elbow for my ld28 (Nissan). Trouble is that parts for it are nonexistent. Some have said there is a fabrication shop who will make one but the trouble with that is I am looking at almost 1200 for one. Then I still have an ld28. Which is a a very uncommon marine engine, not real powerful, old, parts scarce, engine. So is now a good time to repower? I have about 2300 hours on it . thoughts?

the fab shop that gave me the price is from NY. Anyone know a good shop?

Anyhow, i need an exhaust elbow for my ld28 (Nissan). Trouble is that parts for it are nonexistent. Some have said there is a fabrication shop who will make one but the trouble with that is I am looking at almost 1200 for one. Then I still have an ld28. Which is a a very uncommon marine engine, not real powerful, old, parts scarce, engine. So is now a good time to repower? I have about 2300 hours on it . thoughts?

the fab shop that gave me the price is from NY. Anyone know a good shop?