hollywood8118

Guru

- Joined

- Nov 16, 2009

- Messages

- 2,379

- Location

- USA

- Vessel Name

- " OTTER "

- Vessel Make

- Ocean Alexander Europa 40

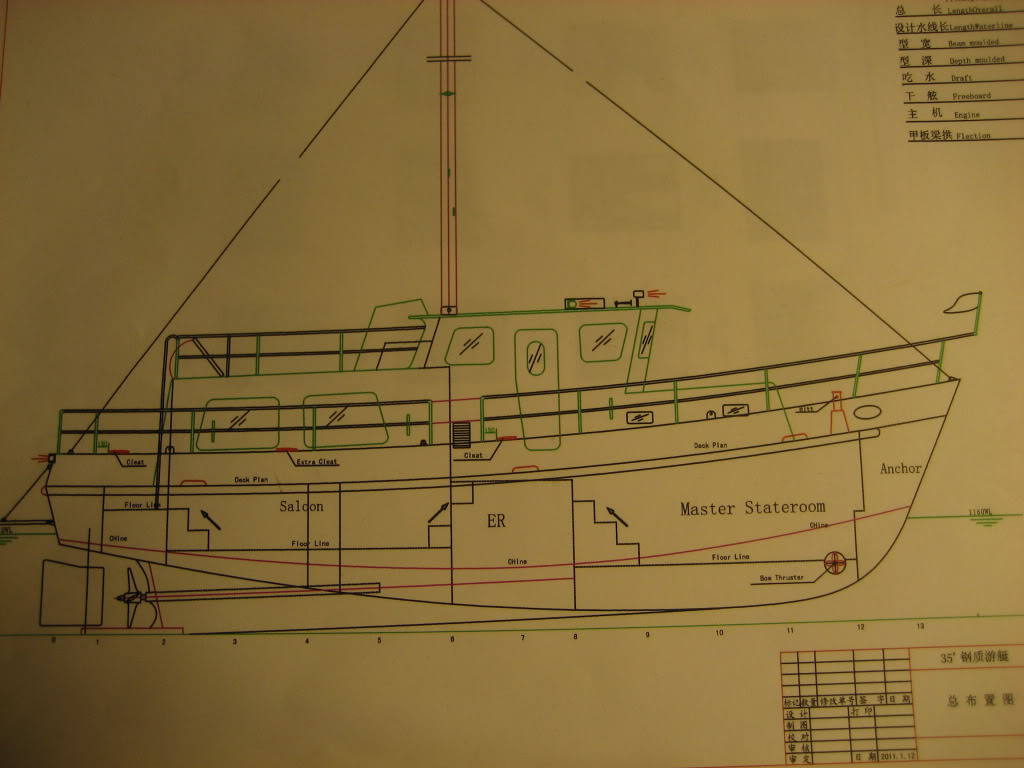

Oh My....

Don't get me started about the inadequate height mast...

The tiny rudder....

And the pointed bow.. if the anchor handler slips it will put a eye out!

HOLLYWOOD

Don't get me started about the inadequate height mast...

The tiny rudder....

And the pointed bow.. if the anchor handler slips it will put a eye out!

HOLLYWOOD