Although everything (except the anchor light) seems to function, I think it's clear why the system cries out for improvement. I've been reading the books and the interwebs on the subject and deficiencies include a lack of circuit protection in the battery room, unidentifiable circuits, electric and electronic add-ons that are not integrated into the system, and so on. Both batteries are relatively new.

Some questions I have:

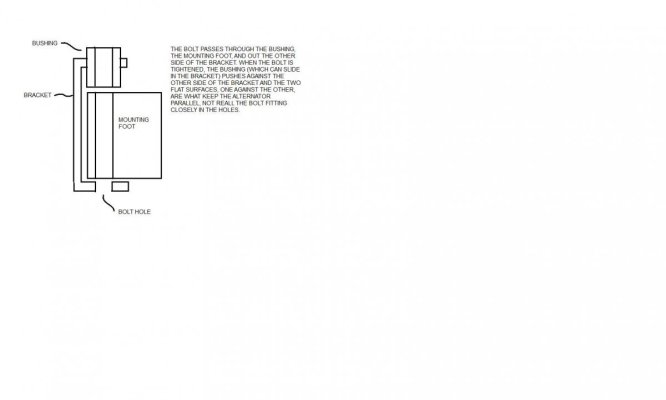

Diagram:

- what is the unit inserted between the Pos battery terminals? - not evident in the actual pic of the batteries.

- I want to increase the size of the alt-starter cabling, but which wire (looking at the starter pic) is the right one?

- I suspect the alt pulley is out of alignment

Front wiring pic:

- Cannot figure out what all those small wires to the left and right of the Pos bus are. The Pos bus is the black disc and the black wire attached to it comes from the switch to feed the panel above.

Panel back:

- Best way to identify what is what? Or just take it all out ans start over, incorporating the VHF and depth into a new breaker/switch panel?

- The horn, fuel pump and bilge pump have toggle switches on the console already.

Basically, any input to give me hints, shortcuts etc. greatly appreciated!