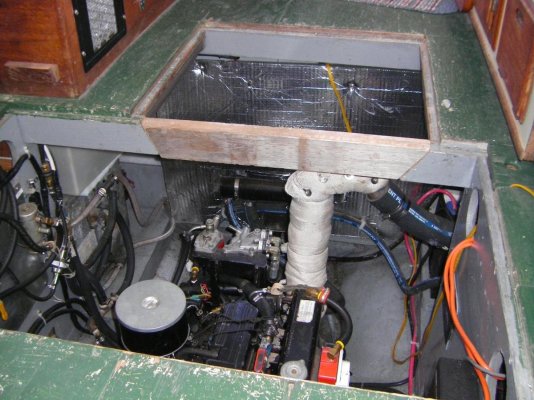

We did a sea trial today on a Mainship 350/390 with Yanmar 170s (4LH-DTE-93) with about 750 hours on the engines. It is propped with 22-19 wheels. Our mechanic and the Yanmar manual say that WOT should turn about 3300 RPMs but we were only able to achieve 2700. In speaking with the owner and broker they say that 2700 RPMs has always been the max that they obtain since it was purchased 6 years ago.

The mechanic thought the engines were well maintained, ran fine and he did not find any issues with them. From my research it seems like the cause of this

could simply be the high speed screw setting that limits the throttle or it

could be over propped however the engine showed no sign of overloading.

We are looking to run efficiently and are not overly concerned with speed.

I would appreciate any thoughts on what we are seeing and any potential issues that we should be concerned about given what we are seeing.

Thank you in advance for any thoughts and/or advice you can provide.

The mechanic thought the engines were well maintained, ran fine and he did not find any issues with them. From my research it seems like the cause of this

could simply be the high speed screw setting that limits the throttle or it

could be over propped however the engine showed no sign of overloading.

We are looking to run efficiently and are not overly concerned with speed.

I would appreciate any thoughts on what we are seeing and any potential issues that we should be concerned about given what we are seeing.

Thank you in advance for any thoughts and/or advice you can provide.