Codger2

Guru

- Joined

- Oct 11, 2007

- Messages

- 6,691

- Location

- US

- Vessel Name

- Circuit Breaker

- Vessel Make

- 2021..22' Duffy Cuddy cabin

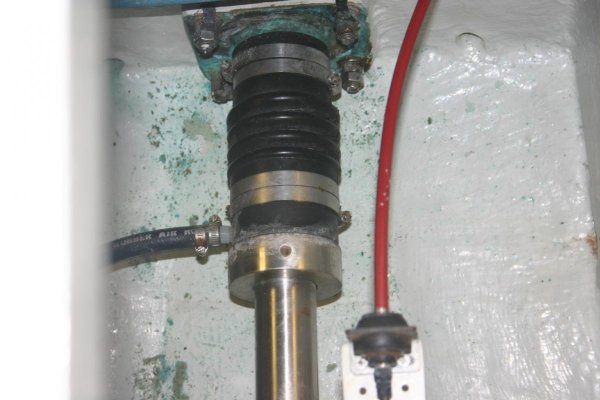

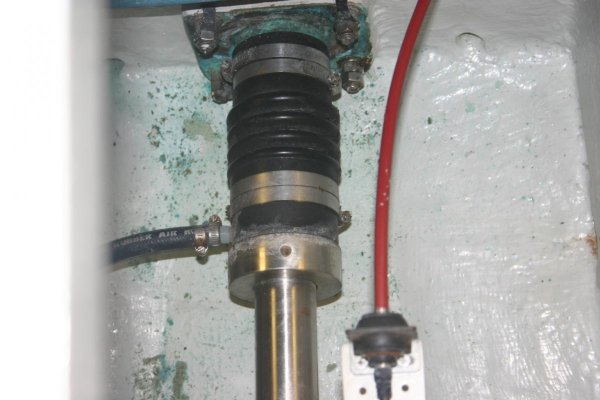

PYI (PSS) Shaft Seal Leaking

My dripless shaft seal is leaking when underway. (It's fine when not in gear or engine off.) Not alot but just enough to fling water spray in the ER. I went to a yard and ask how much to pull the boat and replace the seal. (Kit?) The manager said to just burp the bellows, allowing the inrush of water to flush out the sealing surface, polish the two surfaces with 600 paper, then loosen the 4 set screws on the SS collar and increase the load on the coil spring. (About an inch)

Has anyone done this? The seal is 9 years old and maybe due for a complete replacement.

Any advice is welcome other than "don't put the boat in gear."

My dripless shaft seal is leaking when underway. (It's fine when not in gear or engine off.) Not alot but just enough to fling water spray in the ER. I went to a yard and ask how much to pull the boat and replace the seal. (Kit?) The manager said to just burp the bellows, allowing the inrush of water to flush out the sealing surface, polish the two surfaces with 600 paper, then loosen the 4 set screws on the SS collar and increase the load on the coil spring. (About an inch)

Has anyone done this? The seal is 9 years old and maybe due for a complete replacement.

Any advice is welcome other than "don't put the boat in gear."

)

)