Yes, Bruce, they were combo brass and plastic like this.

I found a replacement cap today from the local marine supply that fits.

A second is on order as a replacement for the other side. These new caps make my deck fills look like crap! Now I'll need to break out the chrome paint left over from my lower helm leather wrap project to improve the look.

The fuel polisher showed up today for the job. Duke and Charlotte are the husband/wife team of Cruising Seas Services. They are great folks who are professional, thorough and a pleasure to spend the day with.

They set up their filtration cart on the dock ...

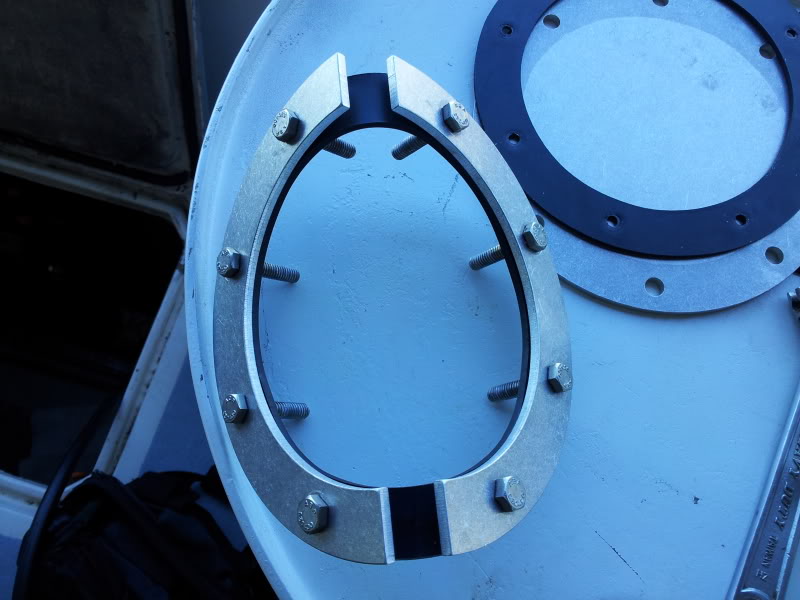

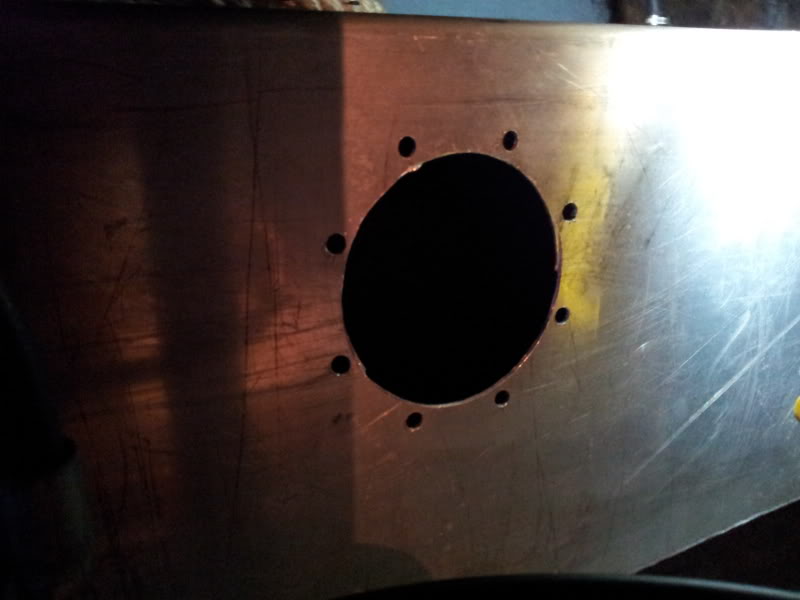

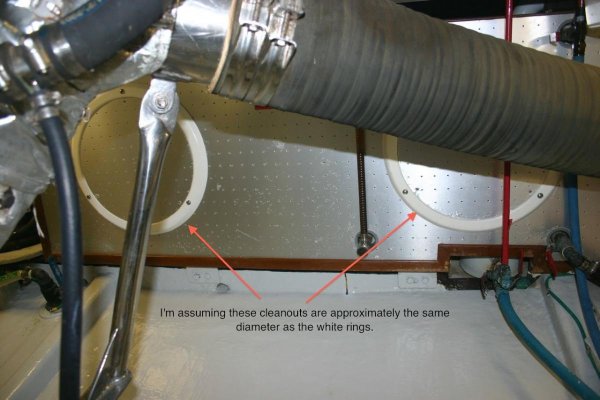

and loaded two 55 gallon drums in the cockpit to handle the fuel. Duke explained to me that they'd pump all but the last 10 gallons or so from the tank before cutting the holes. The reason for this is that the crud at the bottom of the tank can release hydrogen which causes an ignition/explosion hazard. If the bottom stays covered with diesel fuel, this problem prevented. The 6 inch access hole and 8 screw holes were cut uneventfully.

After the holes were cut, the tank was emptied completely.

The port tank came through with flying colors. The fuel looked great and the tank did not show signs of contamination or bacteria presence.

I have been hunting for the source of a persistent, but intermittent, fuel leak that sometimes would leave a few drops in a pan and other times a few ounces. For months I have been searching unsuccessfully for the source. Duke found a fitting at the tank outlet that was

very slightly loose.

With the tank empty, he was able to remove the fitting. It showed signs of being installed with thread sealant which he removed. The fitting was reassembled properly with tape and the area cleaned thoroughly. I'll monitor it closely for further leakage. I'm hopeful that this was the source.

After the access plate was installed, the fuel was returned to the tank and the tank checked for leaks.

By this time, it was approaching 3PM, so Duke decided there was not enough time to comfortably finish today. We arranged to reconvene tomorrow morning to complete the stbd side. I appreciate the fact that he would rather work a 2nd day than rush to complete the job today. I want this done thoroughly and correctly the first time and I'm convinced watching their team work that it will be done right.

As it turns out, the Admiral is home entertaining a former neighbor lady who returned to town for the week and is staying at our house. They have LOTS to talk about apparently b/c they had not stopped talking when I left last night and reports are that they stayed up until midnight catching up. Damn! Another night on the boat!!

I'll report back tomorrow with the epilogue.

Thanks, Art!

Thanks, Art!

Also we found that although my SS waste and water caps are the same OD, they have different threads. I field repaired the broken cap with JB Weld Putty to make due until new caps are found. So I'll return these and look locally for a good replacement.

Also we found that although my SS waste and water caps are the same OD, they have different threads. I field repaired the broken cap with JB Weld Putty to make due until new caps are found. So I'll return these and look locally for a good replacement.