RT Firefly

Enigma

Greetings,

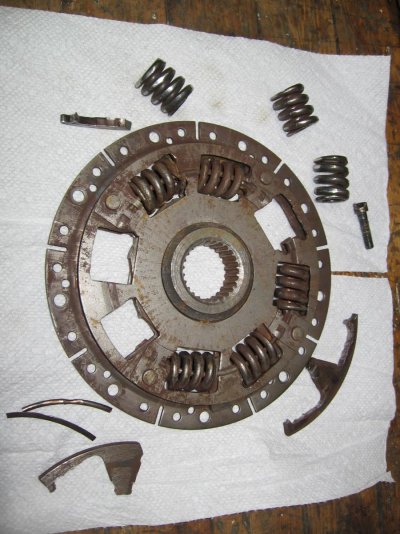

Is there any "average" service life for a damper plate? Should they be changed under a preventative maintenance program at XXX (NOT what you think it means) hrs? Is there any "warning" before they self destruct?

I realise the service life is probably dependent on number of shift cycles or some such criteria. Any opinions?

Thanks.

Is there any "average" service life for a damper plate? Should they be changed under a preventative maintenance program at XXX (NOT what you think it means) hrs? Is there any "warning" before they self destruct?

I realise the service life is probably dependent on number of shift cycles or some such criteria. Any opinions?

Thanks.